Articles

The Scope and Application of Electrical Signature Analysis in Windpower

Electrical Signature Analysis (ESA) was initially developed at Oak Ridge National Labs (ORNL) in the 1980s as a method for evaluating bearings and gears in motor operated valves in the nuclear power industry. In 1992, the technology was licensed into general industry for applications in utilities and commercial applications...

- Howard Penrose

- MotorDoc LLC

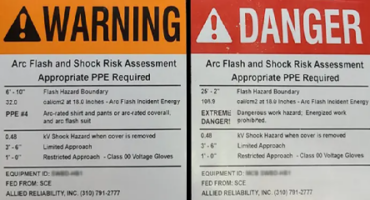

Arc Flash Studies: Why and When Are They Required?

For employees to work on exposed live (energized) circuits, an arc flash hazard assessment is needed to determine the incident energy available at the equipment and what personal protective equipment (PPE) is needed to work safely...

- Michael Levitt

- Allied Reliability

The Disturbing Direction of Condition-Based Monitoring

Terms like predictive maintenance, condition based maintenance, and reliability-centered maintenance, have undergone commercially-driven changes for over 30 years...

- Howard Penrose

- MotorDoc LLC

Detection of Gearbox Damage During Operation

Institute for Machine Elements at the University of Stuttgart detects smallest fraction on gear flank surface with the help of a SONOTEC ultrasound sensor.

- Christian Probst

- SONOTEC GmbH

Intrinsically Safe Vibrations Sensors Enable Condition Monitoring in Hazardous Locations

Vibration monitoring is essential for predictive maintenance of rotating machinery. This is no less true in hazardous locations, and certified sensors designed for these locations are readily available. Below, we’ll focus on Intrinsically Safe sensors, which meet the requirements for hazardous locations found in chemical processing facilities, refineries, mills, and other facilities where flammable materials are processed or handled...

- Peter Eitnier

- Wilcoxon Sensing Technologies

Manual or Automatic Lubrication? How to Decide

Lubrication is an essential part of machinery maintenance for nearly every production facility. On average, lubricant purchases only amount to 3 percent of a maintenance budget, but lubrication-related activities can influence an estimated 40 percent of total maintenance costs...

- Robin Marcinkus

- UE Systems

How do You Ensure Your Training Investment Changes Behavior and Produces Results?

Finding, developing and retaining talent is one of the most important priorities for industrial and manufacturing leaders today. By providing development opportunities to your teams, you’re inviting a strategic, intentional investment in your people that can motivate employees to stay and grow with your organization, filling current and forecasted needs and roles...

- Tara Holwegner

- Life Cycle Engineering

Digitalizing Traditional Sensor Technologies with IO-Link

Learn how IO-Link has changed the smart sensor industry, enabling you to adapt your current sensors to offer secure digital output, customize your system, and make smarter, data-driven decisions—all while reducing the costs of streamlining data.

- Bob Martin

- IMI Sensors

Commercial and Industrial Power System Losses and Mitigation through Neutral and Ground

Even in discussions related to power harmonics most engineers, let alone reliability and energy professionals, understand the potential losses through the system. When it comes to harmonic content in neutral and ground in single and three phase systems, and the related losses, there has been limited attention...

- Howard Penrose

- MotorDoc LLC

- 1

- 2

- 3

- …

- 9