Articles

Online Vibration, Ultrasound & Temperature Data Integration Monitoring

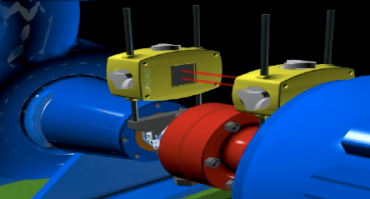

In today’s modern world information is found all around us and it is available at the simple push of a button; 24/7/365. Machine condition monitoring systems (online systems) have been around for quite a while, but they have typically been reserved for the most critical and most expensive machines at a facility...

- Dave Leach

- LUDECA

Motor Testing, Which Road Will You Take?

There are twelve interdependent elements in planned maintenance that are integral to a successful process. Each element contributes to and provides support for the others. The linked elements, in total, provide the base for the Planned Maintenance Process...

- Dave Humphrey

- Allison Transmission

Using Ultrasound to Improve Lubrication Practices

Keeping a handle on lubrication is easy, right? All one needs to do is make sure the right lubricant is used in the right amount and at the right time. Not so fast; if only it were that simple...

- Adrian Messer

- UE Systems

The Key to Machinery Reliability

The goal of Minnkota’s PPM (planned preventative maintenance) Team is to use their technologies and resources to provide the workers with safe, reliable operating equipment and make a positive impact on their maintenance...

- Tod Baer

- Minnkota Power Cooperative Inc.

CMMS – Friend or Foe?

In every good maintenance program, there needs to be a place to store a history of problems found and actions taken if we are to learn from our experiences and continuously improve...

- Paul Dufresne

- Reliability Playbook, in Partnership with Lubrication Engineers

Go Beyond Condition Monitoring; Condition Improvement

We all know what a great job vibration analyst’s perform. They are all that stands between a manageable plant and the chaos and mayhem that can result from machines failing unexpectedly...

- Jason Tranter

- Mobius Institute

Prevent Future Faults; The Ultimate Challenge for Analysts

Vibration analysts shouldn't detect misalignment that results from poor alignment practices. Vibration analysts shouldn't detect cavitation. And vibration analysts shouldn't detect faults in rolling element bearings...

- Jason Tranter

- Mobius Institute

The Vibration Analyst: Which “Type” Are You?

Vibration analysis of rotating machinery is very challenging; there is a lot to know and there is a lot of pressure to get it right. That knowledge can be gained through experience and formal training. The best analysts result from a combination of the best training (and lots of it) and the richest experience...

- Jason Tranter

- Mobius Institute

The Role of the Plant EAM/CMMS and Why a RIMS is Needed

Plant or enterprise asset management systems like SAP, Oracle, and Maximo are often developed for accounting and lack the definition of components like motors and gearboxes in the functional location structure...

- Forrest Pardue

- 24/7

- 1

- …

- 5

- 6

- 7

- 8

- 9