Case Studies and Stories

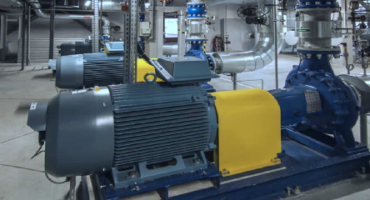

Vibration Analysis Report of Chilled Water Pump

Due to unexpectedly high vibration levels in a newly commissioned chilled water pump located at Tampines Mall, Alstern Technologies Singapore Pte Ltd engaged SPM to conduct a comprehensive vibration analysis. This analysis involved on-site testing, including run-up and coast-down tests.

- Aung Zay Yar Min

- SPM Instrument

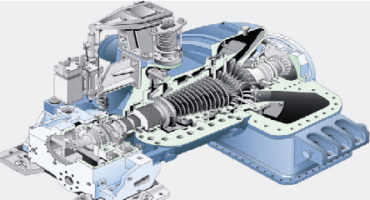

Electrical and Current Signature Analysis of Electric Motors and Driven Equipment

The paper identifies the approach for electrical and mechanical conditions through direct and belt coupled applications and how driven equipment, and loads are evaluated through those coupling types. We will focus on two types of technologies including a 3-phase voltage and current ESA and a single-phase CSA system. The focus will be on CSA but will distinguish what the addition of voltage as part of the measurement will provide.

- Howard Penrose

- MotorDoc LLC

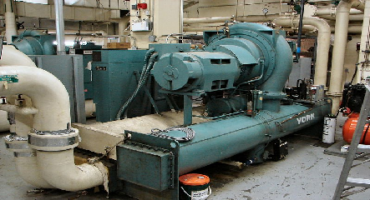

Vibration Spectrum Analysis on Chiller Unit

A call for vibration survey was performed to identify vibratory force that has within the chiller motor and compressor at different vibration location on system.

- Aung Zay Yar Min

- SPM Instrument

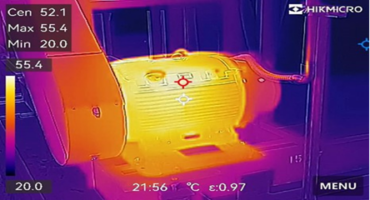

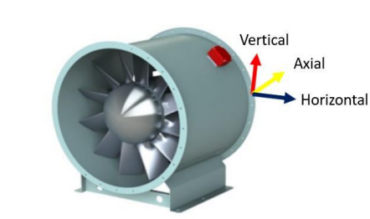

Evaluating a Fan and VFD System with Motor Current Signature Analysis

Both Electrical and Current Signature Analysis (ESA/MCSA) can be used to evaluate conditions of a system and assist in preemptively mitigating defects while optimizing system efficiency based on their specific functions. In the case of this article we will focus on a simple single-phase MCSA tester and a fan system with a variable frequency drive that had a synchronous belt installed...

- Howard Penrose

- MotorDoc LLC

Maintaining Power Plants With Ultrasound – A Success Story

In the biomass power plant of Danpower Energie Service GmbH in Delitzsch, Germany, SONOTEC's ultrasonic testing technology was used to successfully detect various types of leaks.

- Christian Probst

- SONOTEC GmbH

Hamestring Pump Station- Identifying Root Cause

In late 2023, Jacobs implemented an annual Artesis Motor Circuit Analysis PDM for the 7 - 350 HP Pumps at our Hamestring Pump Station in Fayetteville. Three of these are VFD driven...

- Tumay Karaver

- Artesis Technology Systems

Report of Smoke Exhaust Fans’ Vibration Measurement

Vibration measurement is a technique employed to identify and assess the magnitude of vibration in machinery or mechanical systems. It is an important technique in predictive maintenance and can help diagnose faults, especially in the early stages.

- Aung Zay Yar Min

- SPM Instrument

How Improved Lubrication Practices Helped This Air Compressor Save Energy

John Sander discusses how lubrication practices have saved costs and reduced emissions in an air compressor, a knitting plant, and a glass and ceramic producer…

- John Sander

- Lubrication Engineers

Success Story: SONOTEC X PD Energy GmbH

Ultrasound is the technology for the first step in damage detection and has the advantage over other methods in that it can be used at all bearing speeds. Even with extremely low-speed bearings, damage can be detected at the earliest possible stage.

- Christian Probst

- SONOTEC GmbH

- 1

- 2

- 3

- …

- 10