Case Studies and Stories

Avoiding Unplanned Downtime: Online Monitor of Critical Bearings

Keeping a close eye on the condition of critical equipment is fundamental in any industrial facility. When critical bearings fail, it almost always leads to unplanned downtime and interrupted production process, costing companies thousands in production loses. In this case study we will look at how an online monitoring solution using ultrasonic sensors was able to detect an issue on a critical bearing before it turned into a big problem.

- Peter Boon

- UE Systems Inc.

Failure Detection using Ultrasound–Case Study: Slow-Speed Bearing on Oven Motor

Vibration analysis has long been the instrument of choice to use for bearings and other rotating equipment. More commonly, ultrasound is being used in conjunction with vibration analysis to help technicians confirm the condition of mechanical assets.

- Peter Boon

- UE Systems Inc.

Modification on Structure Foundation to Mitigation Resonance Region of Gland Steam Blowers

The Gland steam system is one of the most important systems in the work of the steam turbine, that have function to prevents steam escaping to atmosphere from the HP end of the turbine, and loss of vacuum from the LP end.

- Ahmad Alfakeer

- SEPCO

Why Use ESA? Windpower Case Study

Howard Penrose explains Electrical Signature Analysis (ESA) and how the different parts of 1.6 megawatt GE towers contribute to generating wind power.

- Howard Penrose

- MotorDoc LLC

The Damaging Effect Water Can Have on Your Motors

Moisture: good for plants, never good for electric motors.

- Noah Bethel

- PdMA Corporation

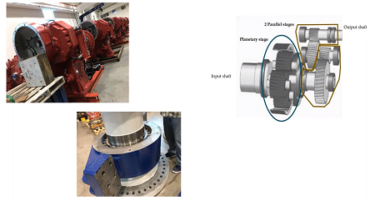

Case Study: Cooling Tower Vibration Monitoring

Cooling towers are a critical component in many process facilities and contain several pieces of rotating machinery that contribute to their operation. Motors, gearboxes, fans and shafts require vibration monitoring to provide technicians with early warning signs of impending failures that could lead to catastrophic breakdowns.

- Peter Eitnier

- Wilcoxon Sensing Technologies

Case Study: Loose Power Connections

A conveyor motor was tested during an annual inspection that operated in the part transfer line. Annual testing for the plant was conducted during a scheduled shut down. Using the automated

routes mode of the & MCA™ Software.

- Bill Kruger

- ALL-TEST Pro

Performing Electrical Signature Analysis on Wind Turbines

Howard Penrose gives an overview on the motors and gearboxes found in wind turbines and goes through case study examples involving electrical signature analysis…

- Howard Penrose

- MotorDoc LLC

Compressed Air Survey leak & Energy Saving Case Study

Compressed Instrument air System is a vital system for the operation of steam and gas turbine control systems like (pneumatic equipment, valves & electrical controls.

….) Therefore, it is important to make it work efficiently and effectively without any problems that might affect its operation & Performance.

- Ahmad Alfakeer

- SEPCO

- 1

- 2

- 3

- 4

- …

- 10