Case Studies and Stories

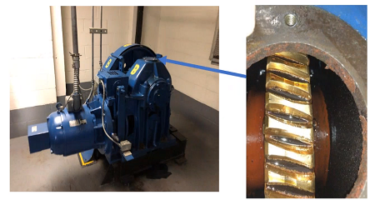

Elevator Motor Case Study: Worm Gear

This case study comes from a geared elevator, specifically from a worm gear located on the 17th floor of a building in NYC. One challenge is figuring out the ratios, because I need to know the details of the gearbox to provide an accurate analysis. With a worm gear…

- Howard Penrose

- MotorDoc LLC

Point of Care Oil Analysis Makes Sense

The 2020 calendar year has certainly brought with it many challenges for a variety of industries. The medical field, pulp and paper industry and food supply chain have all been significantly impacted by the unprecedented COVID-19 pandemic. At the grocery store, people experienced (or are still experiencing) empty shelves, limited food supply and less variety when doing weekly shopping. In March 2020, grocery and supply sales increased 29% from the previous year (3).

- Spectro Scientific

- Spectro Scientific

Plukon Food Group’s Insurability Improved Through Standardising and Centralising Thermographic Inspections

With nearly thirty branches, Plukon Food Group is one of Europe’s larger food companies. The food sector is an industry that has to deal with countless risks that seriously threaten the insurability of such companies.

- Chris Kramer

- I-care

How to Reduce the Hidden Costs and Dangers Lurking Throughout Your Steam System – Continuous, Batteryless Steam Trap Monitoring

This paper will discuss the costs and risks inherent in every steam trap system. We will then explain why two common “solutions” simply don’t solve the problem as well as they could. Finally, we will suggest an easy-to-deploy, cost-effective answer: A continuous monitoring system that uses batteryless sensors to deliver real-time alerting through the cloud, without the need for manual inspection — ever.

- Brian Alessi

- Everactive

Reducing Vibration of Pump Bearing Housing

AVT Reliability® has been involved in resolving a wide range of high operational vibration issues with plant and machinery and including pipework vibration. This has led AVT Reliability® to design and develop a comprehensive range of versatile vibration solutions.

- AVT Reliability

Reducing Costs with ESA and MCA™ Technology

More than 300 million electric motors are used in infrastructure, large buildings, and industry globally. These motors account for about 2/3rds of the industrial power consumption. Electricity is required in almost all areas of the plant to provide the driving force that either operates the equipment that produces the products or provides the services that the plant’s equipment was built to perform..

- Mark Koch

- ALL-TEST Pro, LLC

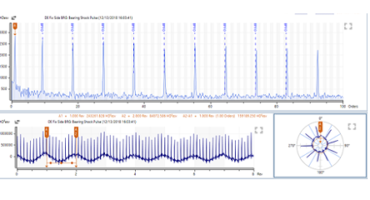

How to Analyse a Bearing Condition

This case study is done in association with a global rail company where VibCloud is utilised for ongoing locomotive monitoring for many years now. Case study demonstrates how to analyse vibration in order to determine bearing condition.

- Petar Spaseski

- iTnnovate

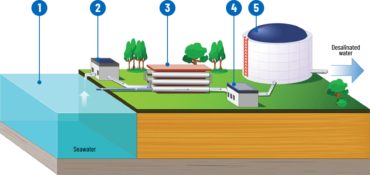

How Condition-Based Monitoring (CbM) Technology Makes Desalination More Energy Efficient

What if we could drink from the ocean? The implications for agriculture, sustainability and global quality of life would be staggering, but so would the demands for energy. Desalinization technology is power hungry, and implementation often comes at a high cost of time and resources..

- Analog Devices

- Analog Devices, Inc

SPM Condition Monitoring Solution for Roller Press

SPM Instrument helps customer around the world to increase the assets availability and reliability. The case study shows SPM HD technology capable of capturing machinery defect at very early stage. The production prolonged for 7-9 months with SPM solution. The technology helps customer to improve the maintenance strategy and provide enough time to plan and act for achieving higher profitability.

- Thamo Yellappan

- Eastwest Online (M) Sdn Bhd

- 1

- 2

- 3

- 4

- 5

- …

- 10