Case Studies and Stories

Digital Maintenance Plan Avoids More Than £25,000 in Wasted Costs for Yelo

Yelo’s manufacturing plant was custom-built to enable it to produce the highest quality vegetable oil and animal feed using only mechanical processes.

Asset availability and reliability is critical to the business and the management team understood that adopting a ‘run-to-failure’ reactive maintenance approach would be both costly and inefficient.

- Frederic Thomas

- AVT Reliability

Rotor Bar Fault Maintenance Issue: Vibration Sensor Alert

A 398 KW MV motor that runs a blower fan in a cement plant was showing strange behavior. The vibration equipment indicated vibration amplitudes that became chronic with the passage of time. The maintenance team, not knowing what the issue was, ran the motor until the bearings had to be replaced...

- Mark Koch

- ALL-TEST Pro, LLC

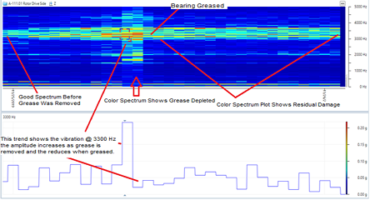

Detecting Lack of Lubrication with Wireless Vibration Sensors

Why wireless sensor Fmax is Critical. Lack of lubrication is a major cause of bearing damage & bearing failure. Therefore, it is critical for vibration sensors to be able to detect the higher frequency vibration resulting from lack of lubrication, which is generally far above 1kHz..

- Mike Olszewski

- Reliability Concepts

Successful PdM Saves Facility Time & Money

A work order was issued by a waste water treatment plant technician requesting electrical support due to a failed floating agitator.

- Mark Koch

- ALL-TEST Pro, LLC

A Most Unusual Problem Solved by Reliability-Focused Common Sense

The vibration and oil data for the gearbox in this Gypsum stirrer was normal. But we knew something was wrong. A borescope camera showed us something astounding...

- Matthew Fallow

- Asset Quality

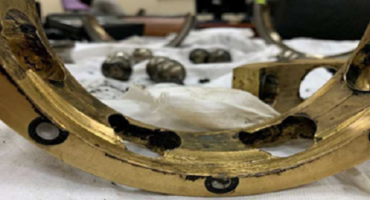

Poor Lubrication – Brass Cages Are Boon

An antifriction bearing generally has 4 major components. In this case study we will discuss how brass cages are better in a highly dusty & contaminated poor lubrication condition...

- Akhil jeet Rathore

- Indorama Petrochemicals & Fertilizers

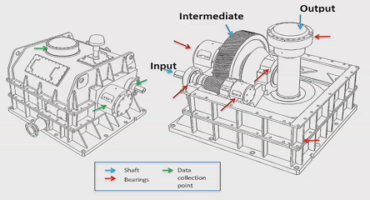

How We Diagnosed Our Cooling Water Pump Gearbox

This case study comes from a custom-made, four-story-high pump at Engro Fertilizers. In January 2014, we started noticing abnormal noise and vibration from the gearbox. But we couldn’t see anything apart from an increased gear mesh frequency…

- Haider Ali

- Engro Fertilizers

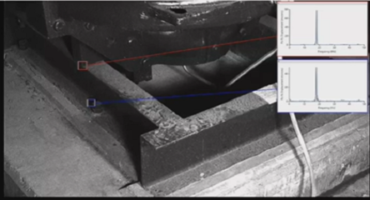

Motion Amplification Helped Diagnose This Vertical Treated Water Pump

This case study shows some of the capabilities of motion amplification technology. This vertical treated water pump was experiencing high vibration, and high lateral motion in line with the suction and discharge piping at the top of the motor when running at around 72%. We decided to take some video footage...

- Andrew Gale

- Optical Motion Technologies

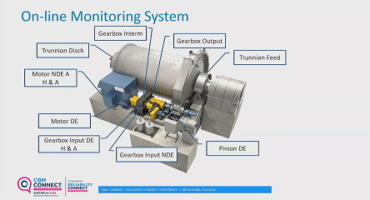

Online Vibration Monitoring System Improves Fault Detection in a SAG Mill

Though we never failed to detect actual failures, there were other things going on: overheating, noise, etc. When those issues arose, we were called to the mine to check the equipment. Of course, this would happen at the most inconvenient times...

- Dana Lake

- ACOEM

- 1

- 2

- 3

- 4

- 5

- 6

- …

- 10