Five Minute Facts

Following Bearing Damage Progression to Failure Mode

When vibration enveloping was introduced several decades ago, it became possible to detect damages in earlier stages than before, and it then became relevant to talk about realistic pre- warning times.

- Ron Kittle

- SPM Instrument Inc

Sensor Reliability Impact on Predictive Maintenance Program Costs

Accelerometers with lower mean time between failures (MTBF) values result in higher costs for permanently installed vibration sensor applications - as much as $60 per vibration sensor. By taking the MTBF and manufacturing quality into account when making an accelerometer purchase, you can achieve lower overall program costs.

- Peter Eitnier

- Wilcoxon Sensing Technologies

Exploring Vibration Analysis Technologies

In the realm of industrial maintenance, understanding the health of machinery is paramount. One of the most effective tools in this pursuit is Vibration Analysis technology. By examining the oscillations and vibrations of machinery, it’s possible to detect early signs of wear, misalignment, and other issues before they escalate into costly failures. In this article, we will delve into the different facets of Vibration Analysis technology and compare Handheld/Portable, Wireless, and Continuous Online Condition Monitoring solutions.

- Florian Buder

- ACOEM

Erratic Vibration Behavior in a Steam Turbine

This machine had shown erratic shaft and pedestal vibration since its inception – the vibration would increase and decrease, predominantly at 1x…

- RAO VAMSIDHAR

- VIZAG STEEL

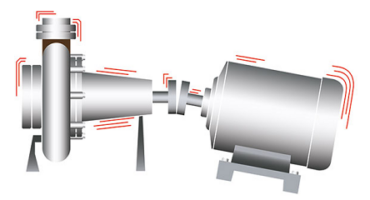

Two Peculiar Cases of Misalignment

Misalignment causes a lot of problems, but it doesn’t always make itself known through vibration. Vamsidhar Rao explains two cases…

- RAO VAMSIDHAR

- VIZAG STEEL

Abnormal 1x Vibration Problem in an Oxygen Compressor

After a major overhaul of an oxygen compressor, 1x vibration was observed in the L.P. discharge bearing. We tried several remedies without success, such as changing the oil pressure and temperature, balancing the rotor…

- RAO VAMSIDHAR

- VIZAG STEEL

Does Your Maintenance Program Need Maintenance?

A “good” maintenance program involves keeping equipment in peak condition and mitigating failure. Getting to this result takes the proper balance of strategies, people, and resources. Mark Frogley explains...

- Mark Frogley

- Acoem USA

Safety Barrier and Intrinsically Safe Accelerometer Compatibility

What is the purpose of the safety barrier? Peter Eitnier describes what goes into a safety barrier, what it prevents, and it's maximum limits it can handle to retain safety.

- Peter Eitnier

- Wilcoxon Sensing Technologies

What’s New in Vibration Analysis?

Matthew Moore details recent changes in ISO vibration standards, MEMS vibration sensors, and other topics…

- Matthew Moore

- Moore Reliability Limited

- 1

- 2

- 3

- …

- 7