Five Minute Facts

What is MCA?

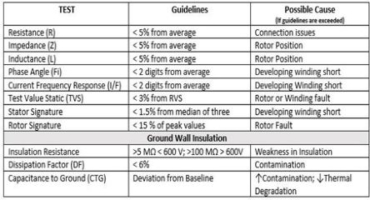

MCA™ is a field proven very easy to use and safe method of evaluating the condition of electrical equipment while the equipment is deenergized. The basic premise of MCA:

- Mark Koch

- ALL-TEST Pro, LLC

Get Sampling Compact Gearboxes & Gearmotors

Many small gearboxes are considered to be replaceable but the downtime they cause cannot be replaced. Oftentimes these gearboxes, though small, are critical to an operation. For example, a breakdown in a conveyor gearbox, burnt out the conveyor belt and brought a large mining site to a halt at a cost of $21,000,000 USD. Learn what tools you can use to perform 2-minute visual checks and oil analysis that can give you information to stay on top of your equipment reliability and manage risk.

- Bernie Hall

- Checkfluid

Fault in Stator of Re-Wound Motor

Do you know the condition of your spare motors? The replacement motor on a critical conveyor belt trips on its first startup. The tools on hand couldn’t identify the problem. Watch this video to see how they resolved the problem.

- Noah Bethel

- PdMA Corporation

Detecting Bearing Faults Using Condition Monitoring Software

There are many faults that cause a rotating component to breakdown and fail, some of the most common being misalignment, unbalance and soft foot. One of the most common faults that cause a component to breakdown are bearing defects.

Why would a company carry out condition monitoring programs?

- Alan Hemphill

- AVT Reliability

Destructive Impact of Heat on Electric Motors

The size of a motor doesn’t matter if it is a critical motor. In this case study had 2 hp motor failed it would have cost $40,000 a day in lost electricity production. See how the technicians using, newly acquired data analysis knowledge, discovered a heat problem with the motor before it failed.

- Noah Bethel

- PdMA Corporation

Proper Grounding Techniques – Avoiding Radio Frequency Interference

Interference of electrical signals, whether through radio frequencies (RF), electromagnetic forces (EMI) or other sources, has long been recognized as an issue that can plague accelerometer applications. This electrical interference can manifest as increased noise, signal interruption, or erroneous data altogether, eroding trust in the measurement system and complicating machine fault analysis.

- Peter Eitnier

- Wilcoxon Sensing Technologies

Would Your Plant Benefit from Fuel Monitoring? Try a Pilot Project!

Before we start a pilot, we make sure we’ve established an opportunity you want to capture. Pick a problem to solve so you can test the downstream benefit…

- Rob Kalwarowsky

- Rob's Reliability

Choosing the Right PM Intervals for Fuel Monitoring

Kevin Dagenais discusses the factors one must consider when determining PM intervals for fuel monitoring…

- Rob Kalwarowsky

- Rob's Reliability

The Damaging Effect Water Can Have on Your Electric Motors

This case study discusses the damaging effect water can have on an electric motor. Also discussed is the testing required to diagnose the problem with the motor and the cost savings by detecting and diagnosing the problem early.

- Noah Bethel

- PdMA Corporation

- 1

- …

- 10

- 11

- 12

- 13

- 14

- …

- 28