Five Minute Facts

Switching Strategies: Moving to Condition Based Maintenance

Balancing cost reduction and efficiency improvement targets is a common source of frustration for maintenance and engineering managers. For facilities that operate continuously with no window for unplanned shutdowns, poor reliability and availability of machinery is far more serious, but even in factories with regular opportunities for maintenance, recovery can still be expensive and time consuming.

- AVT Reliability

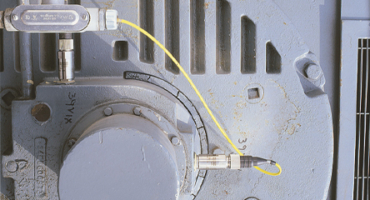

Improving Oil Cleanliness – Your 2021 Maintenance Resolution – Part 1

Is increasing oil cleanliness on your 2021 to-do list? Oil contamination continues to be one of the biggest causes of component failure and productivity declines. Oil cleanliness starts at the beginning with inspecting and filtering your new and incoming oil.

- Bernie Hall

- Checkfluid

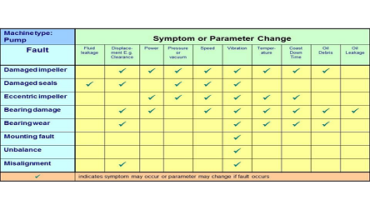

Gear Defects and Faults

Gear faults typically occur in the teeth of a gear mechanism due to fatigue, spalling, or pitting. These can be manifested as cracks in the gear root or removal of metal from the tooth surface. Gears are the main elements of power transmission in many industrial applications and are subjected to significant stresses and loading.

- Dara O'Sullivan

- Analog Devices, Inc

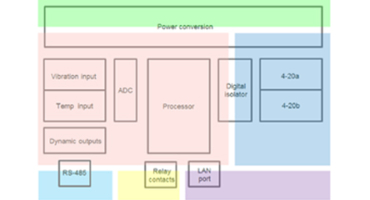

Galvanic Isolation in Signal Conditioners: Why is it Important?

Galvanic isolation was developed as a response to galvanic paths and subsequently, the signal interference they cause. A galvanic path is defined as a path in which there is a direct electrical connection between two or more electrical circuits that allow current to flow..

- Peter Eitnier

- Wilcoxon Sensing Technologies

Triaxial v Single Axis – More for Less

Over the years, advancement in microchip technology and minimisation of condition monitoring devices has led us to the next generation of condition monitoring triaxial sensor..

- AVT Reliability

4-20 mA vs. IEPE Vibration Sensors for Process Control Systems

With process control systems, it’s simple (and smart) to incorporate vibration data into an existing monitoring program. Either loop-powered 4-20 mA sensors, which output a direct 4-20 mA signal, or IEPE sensors, which output dynamic data that can be converted into an acceptable process signal, can be used..

- Elise Brannon

- Wilcoxon Sensing Technologies

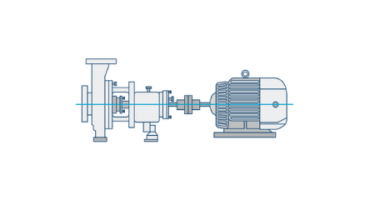

Detecting and Diagnosing Misalignment in a System

Next-generation sensors based on MEMS technology, combined with advanced algorithms for diagnostic and prognostic applications, expand opportunities to measure a variety of machines and improve the ability to effectively monitor equipment, improve uptime, enhance process quality, and increase throughput. This 5 minute fact reviews misalignments and their characteristics to provide insights into some of the key system requirements that must be considered when developing a condition-based monitoring solution.

- Pete Sopcik

- Analog Devices, Inc

How Many Averages

Signal processing in the FFT analyzer or vibration data collector includes averaging. How many averages should you take to reduce noise and produce an accurate vibration spectrum?

- Jason Tranter

- Mobius Institute

Peak Hold Averaging

Averaging - understanding peak hold averaging in the FFT analyzer, signal processing, noise reduction, FFT analysis in vibration data collector FFT analyzer, number of averages.

- Jason Tranter

- Mobius Institute

- 1

- …

- 11

- 12

- 13

- 14

- 15

- …

- 28