Five Minute Facts

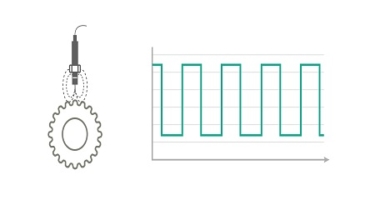

Sensors for speed measurements

Choosing the right speed sensor for turbomachinery is of crucial importance for an accurate and reliable measurement. After all, the signal of the sensor is the input for an overspeed protection system. A faulty sensor leads to an unreliable input signal, which has a negative influence on the accuracy and reliability of the protection system.

- Istec International

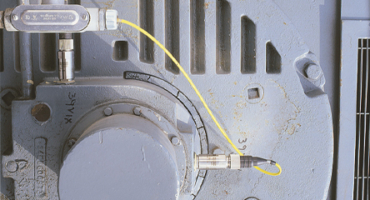

Proper Grounding Techniques – Avoiding Radio Frequency Interference

Interference of electrical signals, whether through radio frequencies (RF), electromagnetic forces (EMI) or other sources, has long been recognized as an issue that can plague accelerometer applications. This electrical interference can manifest as increased noise, signal interruption, or erroneous data altogether, eroding trust in the measurement system and complicating machine fault analysis.

- Peter Eitnier

- Wilcoxon Sensing Technologies

4-20 mA vs. IEPE Vibration Sensors for Process Control Systems

With process control systems, it’s simple (and smart) to incorporate vibration data into an existing monitoring program. Either loop-powered 4-20 mA sensors, which output a direct 4-20 mA signal, or IEPE sensors, which output dynamic data that can be converted into an acceptable process signal, can be used..

- Elise Brannon

- Wilcoxon Sensing Technologies

How Many Averages

Signal processing in the FFT analyzer or vibration data collector includes averaging. How many averages should you take to reduce noise and produce an accurate vibration spectrum?

- Jason Tranter

- Mobius Institute

Peak Hold Averaging

Averaging - understanding peak hold averaging in the FFT analyzer, signal processing, noise reduction, FFT analysis in vibration data collector FFT analyzer, number of averages.

- Jason Tranter

- Mobius Institute

Spectral Resolution-Averaging

Averaging and lines of resolution in FFT analyzer vibration spectrum. How many averages to take, data collection time in spectrum analyzer vibration data collector.

- Jason Tranter

- Mobius Institute

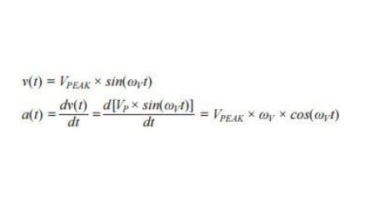

MEMS Vibration Sensing: Velocity to Acceleration

MEMS accelerometers are just now coming of age as vibration sensors in modern condition monitoring (CM) systems. Recent expansion of capability in measurement range, bandwidth, and resolution is enabling new concepts and system architectures...

- Mark Looney

- Analog Devices

Machine Health Basics For The OEM Design Engineer

Analyzing machine vibration as a means of monitoring healthy operation and diagnosis of emerging problems is a relatively mature specialization, long practiced on turbines and motor-pump trains. Condition Monitoring for the factory today is generally implemented by a skilled practitioner equipped with a handheld data-logger, collecting and processing signals from a tethered vibration sensor during a periodically scheduled, route-based maintenance program.

- Ed Spence

- The Machine Instrumentation Group

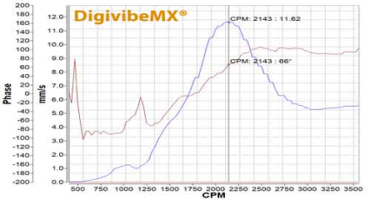

Resonance & Natural Frequency

Have you ever been trying to balance a fan and its vibration doesn't go down, no matter what you do? Do you know what resonance is?

- Dr. Thierry Erbessd

- Erbessd Instruments

- 1

- 2

- 3

- 4

- 5

- …

- 7