Five Minute Facts

Optimizing and Extending Oil Drain Intervals

There is a wide variety of valves available when trying to decide which sampling valve is the best for optimizing oil change intervals. One thing to remember is that recommended oil change intervals are typically conservative estimates based on the most rugged conditions.

- Bernie Hall

- Checkfluid

Gold Mine Strikes Mother Lode, Decreases Lubricant Use by 7x!

Using a competitor’s asphaltic-based open gear lubricant to lubricate the ball mill’s open gear, the mine was concerned about the above average operating temperatures and excessive lubricant consumption – requiring one new quarter drum nearly every week.

- John Sander

- Lubrication Engineers

Maintaining Clean Oil for Hydraulic Systems

Did you know that nearly 80% of all hydraulic systems problems can be traced back to contaminated fluid? An effective hydraulic fluid cleanliness program with proper monitoring, and management of fluid condition and cleanliness, can improve the system efficiency, performance, and lifespan of your hydraulic systems operations. Here is some information on the impact a fluid sample can make to maintaining and monitoring hydraulic fluid cleanliness.

- Bernie Hall

- Checkfluid

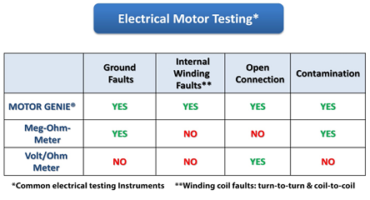

How to Check Your Windings on Three Phase Motors

Motor windings are conductive wires wrapped around a magnetic core; they provide a path for current to flow to create then magnetic field to spin the rotor. Like any other part of the motor, the winding can fail.

- Bill Kruger

- ALL-TEST Pro

Fluting: Beyond the Motor

Before scrolling past what may appear to be another boring article about fluting, VFD’s, grounding brushes and ceramic bearings, I urge you to read on and join in the discussion.

- Matthew Knuth

- SPM Instrument

Motor Acceptance Testing

Motor acceptance testing is a critical part of many preventive maintenance programs and can be key to catching electrical problems before they cause considerable downtime.

- Bill Kruger

- ALL-TEST Pro

How to Detect Early Stage Defect Using I-DNA Technology

Learn how to use Predictive Maintenance in your industrial environment, and see the benefits of putting I-DNA Technology Algorithms into your Predictive Maintenance Program.

- Pieter Van Camp

- I-Care Group

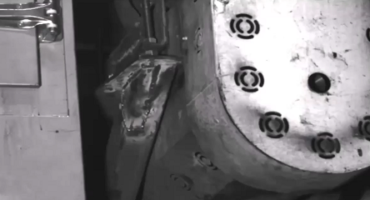

Motion Amplification Case Study: Structural Looseness

This case study features a convection oven fan used in the customer's production process. Multiple welds and other repairs were made prior to the inspection. A service team was called in to balance the fan, but with Motion Amplification it quickly became clear that there was a serious structural issue.

- Andrew Dougherty

- RDI Technologies

Underwater Vibration Sensor Selection

Underwater vibration monitoring can be accomplished through various methods and sensor styles. Peter Eitnier discusses some of these methods in more depth.

- Peter Eitnier

- Wilcoxon Sensing Technologies

- 1

- …

- 4

- 5

- 6

- 7

- 8

- …

- 28