Five Minute Facts

Leak Detection with Ultrasound: How Does It Work?

Leaks can form practically anywhere in a plant. This includes pressurised systems and systems under a vacuum.While it is important to locate potential safety hazards from leaks, the loss of gases through leaks can be very costly.

- Adrian Messer

- UE Systems

What Are Rolling Element Bearing Defects And What Causes Them?

Rolling element bearing defects are typically artifacts of mechanically induced stresses or lubrication issues that create small cracks or defects within the mechanical components of the bearing, leading to increased vibration.

- Pete Sopcik

- Analog Devices, Inc

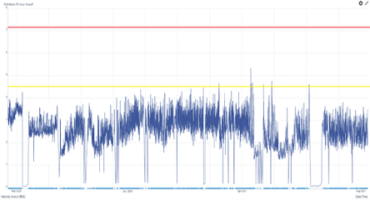

Automatic fault detection in machinery using narrow spectral bands

Spectral bands can be a very useful tool for the detection of machine faults. However, not all condition monitoring analysts use them or take advantage of their full potential.

- TWave

- TWAVE

Dependable Grease for Industrial, Fleet, Farm & Marine

Suitable for a wide variety of industrial, fleet, farm and marine equipment in a broad operating temperature range, Monolec Multiplex Lubricant provides dependable performance in critical grease points including chassis and wheel bearings. This versatility makes it possible to consolidate the number of greases used and stored onsite.

- John Sander

- Lubrication Engineers

Ask the Expert: Compressor Oil Analysis

What is a compressor? Ask the expert explains how different compressors work. 45% of compressors sold in the industry are primarily for compressed air...

- Spectro Scientific

- Spectro Scientific

Developing a Successful Motor Maintenance Program – Part 1

What makes your electric motor maintenance program a winner? Answer: A good Quality Control program from cradle to grave along with Trending Data and Troubleshooting. Watch this video to see how one part of the program, Quality Control, helps you reach your goal of a winning program in your facility.

- Noah Bethel

- PdMA Corporation

Brewery Saves Big by Extending Compressor Oil Life

With regular oil analysis to ensure oil quality and cleanliness, the drain intervals for all four air compressors were extended up to eight times the OEM-recommended interval of 8,000 hours. Total cost savings – on oil alone – was $71,000. Environmental impact was reduced as well, with 1,035 fewer litres (273 fewer gallons) of waste oil. Fewer oil changes also meant less downtime, maintenance and labor. The overall effect for the company was significant cost savings on oil, maintenance time and disposal.

- Preston Rubottom

- Lubrication Engineers

How Does the Infravision Application Work and How is a Thermographic Inspection Done?

Thermographic inspections offer many advantages as it helps to ensure a safe working environment and an increase in uptime. It also provides companies with accurate insights into the risks that undermine the continuity of their production lines (and the possibility to actively reduce these risks).

- Chris Kramer

- I-care

Sensors for speed measurements

Choosing the right speed sensor for turbomachinery is of crucial importance for an accurate and reliable measurement. After all, the signal of the sensor is the input for an overspeed protection system. A faulty sensor leads to an unreliable input signal, which has a negative influence on the accuracy and reliability of the protection system.

- Istec International

- 1

- …

- 7

- 8

- 9

- 10

- 11

- …

- 28