Two Minute Tips

Understanding Vibration in Planetary Gears: Detection and Causes

Planetary gear systems are marvels of engineering, offering high torque density and efficiency. However, vibrations in these systems can signal underlying issues that, if left unchecked, may lead to costly failures.

- Motaz Abdelsalam Mohamed

- Mobius Institute

Join Us at Reliable Plant Conference 2025!

The Reliable Plant Conference & Exhibition, co-located with the Machinery Lubrication Conference & Exhibition, is a 4-day event dedicated to the latest trends and tactics in maintenance and reliability. With expert-led learning sessions, access to cutting-edge tools and technologies offered by over 100 exhibitors, and powerful networking experiences, this is a can’t-miss event for anyone looking to transform their maintenance strategy.

- Noria Corporation

Cavitation: Definition, How to Detect and How to Prevent

Cavitation occurs when the liquid in a pump turns to a vapor at low pressure. It occurs because there is not enough pressure at the suction end of the pump, or insufficient Net Positive Suction Head available (NPSHa). When cavitation takes place, air bubbles are created at low pressure.

- Wael Salman

- Dietsmann France

Why Rotor Blade Failures in Steam Turbines Demand Attention: A Data-Driven Perspective

Steam turbines are the workhorses of thermonuclear power plants and large ships, but their efficiency and safety hinge on one critical component: the rotor blade. Last-stage rotor blades (LSRBs) are prone to failure due to prolonged exposure to high-speed wet steam (HSWs). These failures aren’t just costly—they can lead to catastrophic accidents, with fractured blades causing cascading damage to other components running at high speeds.

- Khalid Farooq Khattak

- Fauji Fertilizer Company Limited

Avoiding Bearing Failure Through Proper Grease Management

More than 60% of bearing failures are due to lubrication, and grease failures contribute more than the oil. Whenever the bearings are replaced in the housing, mostly the housing is fully packed with the grease without keeping empty space and started operating the bearing after the housing end cover is sealed.

- Pratap Kambley

- Caravan Reliability Services

Understanding Critical Speed in Rotating Machinery

This article explains the concept of critical speed in the world of mechanical engineering and key points such as natural frequency, resonance and avoidance.

- Motaz Abdelsalam Mohamed

- Mobius Institute

Vibration Monitoring for Paper Machines

Every minute of unplanned downtime for a paper machine represents lost revenue. Maintenance and reliability engineers monitor vibration to avoid costly repairs and breakdowns by detecting early warnings of faults such as imbalance, misalignment, looseness, and lubrication issues.

- Peter Eitnier

- Wilcoxon Sensing Technologies

What’s the Better Bearing: Shield or Sealed?

Very frequently, I receive a common question from customers and followers: Which bearing is best, shielded or sealed? To provide better understanding, I created a simple document that compares shielded bearings and sealed bearings.

- Pratap Kambley

- Caravan Reliability Services

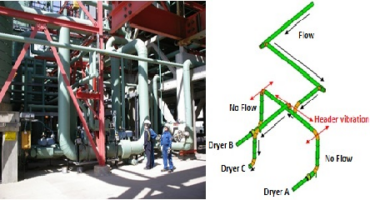

Understanding Piping Vibration: Types, Detection, and Solutions

Piping vibration is a critical issue that can affect the integrity and performance of industrial systems. Let's explore the different types of piping vibrations, how to detect them, and effective solutions...

- Motaz Abdelsalam Mohamed

- Mobius Institute

- 1

- 2

- 3

- …

- 42