Two Minute Tips

Self-Resonance in Sensor Design

There are many things to consider when designing any kind of sensing product, but the main considerations are generally to do with measuring a clean, precise, and isolated signal.

- Gordon Maguire

- Sensoteq

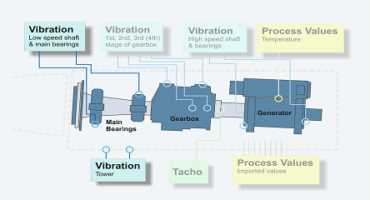

Yaw Bearing System Fault Detected

A case study demonstrates how an effective remote condition monitoring strategy avoids uneconomical operation, costly downtime and consequential damage of wind turbines.

- Michael Hastings

- Brüel & Kjær Vibro (B&K Vibro)

The Big Questions You Must Ask When Getting into Predictive Maintenance

Are you considering predictive maintenance for your assets? Jason Tranter gives you the big questions you should ask first…

- Jason Tranter

- Mobius Institute

Prevent Motor Failure by Keeping Your Motors Clean

One of the easiest ways to prevent premature electric motor failure is to keep your motors clean and free of foreign contaminates. Many electric motors are fan cooled. When contaminates start to build up around the motor, air flow becomes restricted and reduces the ability for the fan to cool the motor which dramatically reduces the life the of winding’s insulation due to the increase in heat.

- Bill Kruger

- ALL-TEST Pro

Protective Coating for Wire Rope, Chains & Cables

Wirelife Almasol Coating Grease (453-451) is a soft, semifluid formulation designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its tacky, water-resistant characteristics enable it to adhere strongly to rapidly moving parts and to seal out damaging moisture.

- John Sander

- Lubrication Engineers

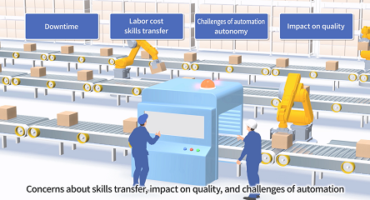

Benefits of Condition-based Maintenance Using AI & Edge Computing

Today's equipment maintenance relies heavily on human labor, while autonomous AI enables both efficient maintenance and increased productivity.

- Daisuke Nishimura

- Macnica

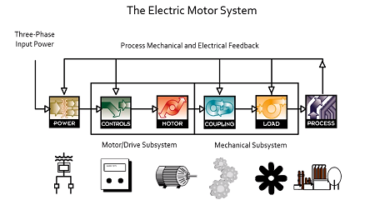

Introducing the Electric Motor System and Electrical Signature Analysis

Howard Penrose gives a brief introduction of the electrical motor system and the variety of monitoring techniques included under Electrical Signature Analysis (ESA): current signature analysis, motor current signature analysis, power signature analysis, and voltage signature analysis…

- Howard Penrose

- MotorDoc LLC

How Does the Cost of Wireless Monitoring Compare?

Are you considering wireless monitoring for your plant but concerned about the cost? David Howard explains how the costs of wireless monitoring compare to equivalent wired systems…

- Dr. M. David Howard

- Erbessd Instruments

Vane Pass Frequency Monitoring

Vane pass frequency is one of the more common and easily identified vibration monitoring components, present primarily in fans and pumps but also identifiable in compressors and other similar rotating equipment.

- Peter Eitnier

- Wilcoxon Sensing Technologies

- 1

- …

- 8

- 9

- 10

- 11

- 12

- …

- 42