Two Minute Tips

Easy Motor Testing Procedures

Professionals in the industries of manufacturing, power generation and water rely on electric motors to complete their objectives. To remain efficient, it is essential that motor-based systems stay in peak operating condition. A sudden motor failure can occur when you least expect it, so understanding procedures for fast motor testing will help you maximize uptime.

- Bill Kruger

- ALL-TEST Pro

Stator Inter-Turn Stress with Electrical Signature Analysis in Variable Frequency Drive Applications

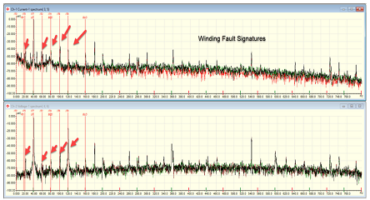

Incorrect settings in a Variable Frequency Drive (VFD) application have an impact on the windings of an electric motor. When a drive is not set correctly, or not tuned when not using straight volts/hertz settings, stresses occur between the turns in a winding. In some cases, this will appear as small Partial Discharges (PD), and in others it can be increased leakage between turns. When these conditions occur, they introduce small current discharges that effect the air gap magnetic field of the motor.

- Howard Penrose

- MotorDoc LLC

Best Kept Secret in Bearing Uptime

Vari-Purpose Lubricant is cool-running, long-lasting, and water-resistant. It dramatically lengthens grease intervals, eliminates bearing failures, can extend bearing life by up to threefold, and does not harden with age.

- John Sander

- Lubrication Engineers

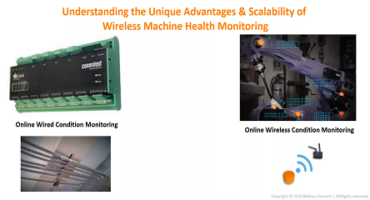

The Evolution of Wireless Monitoring

Wireless monitoring has changed a lot over the past decades, and it continues to improve. David Howard explains…

- Dr. M. David Howard

- Erbessd Instruments

Xport Ultra Lubricator for Remote Grease Lines

The Xport® Ultra automatic single point lubricator is an extremely versatile and capable lubrication system suited to a wide range of applications that demand high lubrication rates and where long remote grease lines are necessary to ensure safe access. It operates fully automatically, independent of temperature, and offers a precise discharge.

- John Sander

- Lubrication Engineers

Beginner’s Guide To Motor Testing

Motors when installed play a critical role in many manufacturing efforts. Businesses in all industries rely on machines to drive profits, so testing these motors ensures your investments are available for demanding tasks.

- Mark Koch

- ALL-TEST Pro, LLC

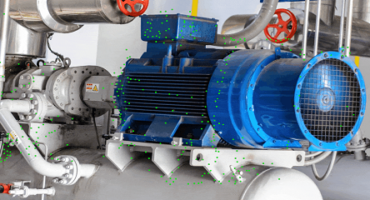

Vibration Tracking – The Looking Glass Technique – See the Invisible

Incredible as it may seem, the vibration (or at least a large part of it) can be detected through video recording with incredible resolution. Saving a huge number of hours in studies that before were time consuming if not impossible to do. All of this using Vibration Tracking.

So, what is the Vibration Tracking? And better yet, what is it for?

- Dr. Thierry Erbessd

- Erbessd Instruments

Safety in Thermal Imaging

Across the world the approach to safety is quite varied, and one can easily become complacent if you do not take a wider view of it. In many forums, regardless of the engineering discipline or matter of social interest, there will be varying views about what is acceptable in terms of safety or what should be common knowledge.

- PJ Cloete

- AVT Reliability

What Is Machine Vibration?

Everyone agrees that vibration data provides information about the condition of the machine and the operation of the equipment, but what exactly is machine vibration? We can say it is an oscillation wherein the…

- Ron Newman

- PRUFTECHNIK

- 1

- …

- 9

- 10

- 11

- 12

- 13

- …

- 42