Two Minute Tips

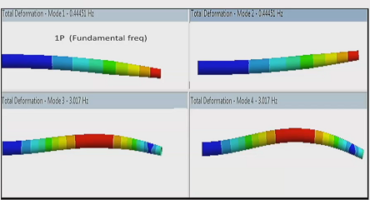

Designing a Wind Turbine: Dealing with Resonance

Whenever the natural frequency of a turbine tower meets the rotor or blade frequency, it oscillates. It has a resonance. How do we avoid it…

- Partha Ravi

- OnyxInsight Australia

Avoid Danger Zones with Wireless Sensors

Minimizing contact with dangerous work areas is one of the simplest ways to keep personnel safe. With the implementation of reliability solutions such as remote condition monitoring sensors, measurements can be recorded from a distance, eliminating the need for employees to enter danger zones...

- Gregory Perry

- Fluke Corporation

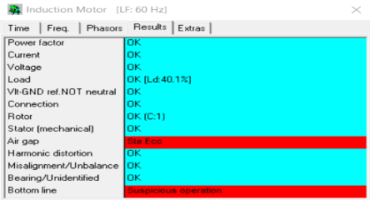

Troubleshooting a Running Motor

This tip discusses troubleshooting the motor and machine train with the motor still running. The fault zones specific to the physical motor are the stator, rotor and airgap....

- Noah Bethel

- PdMA Corporation

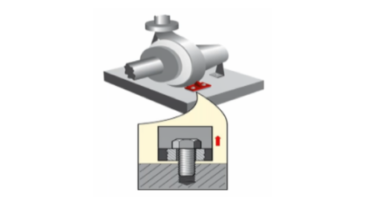

Four Ways Soft Foot Affects Machinery

Soft foot is a condition that occurs when rotating machinery is positioned incorrectly ─ specifically, when one or more of the “feet” of a machine’s base, frame, or soleplate are not making the same point contact as the others...

Surface Morphology of Railroad Tracks

Surface morphology is a detailed study of a surface. We studied the surfaces of railroad tracks and found that using analytical imaging helps us see what we cannot see with our naked eyes…

- Ashish Arora

- Institute of Noise & Vibration

What is Soft Foot and Why Should We Care About It?

Soft foot occurs when rotating machinery is positioned in place on its base, frame, or soleplate, and one or more of the “feet” are not making good contact...

- Frederic Baudart

- Fluke

Setting Acid Number and Base Number Limits

There is a rule-of-thumb that oil should be condemned at double its new oil Acid Number, or at half of its new oil Base Number. The problem with this rule is that is has too many exceptions to be valid. Rather than identify the valid instances, it is better to understand how to derive a correct limit for any application..

- Evan Zabawski

- TestOil

Static Eccentricity Faults Using Electrical Signature Analysis

Static Eccentricity (air gap) is a fault that is created when the rotor is not in the magnetic center of the stator. Static eccentricity can cause an increase in operating current, overheating, energy losses, and overloading of bearings...

- Mark Koch

- ALL-TEST Pro, LLC

How to Measure and Use Reliability Metrics

Maintenance and reliability managers must have metrics in place to identify needs for improvement.

- Warren Wu

- UpKeep

- 1

- …

- 16

- 17

- 18

- 19

- 20

- …

- 42