Two Minute Tips

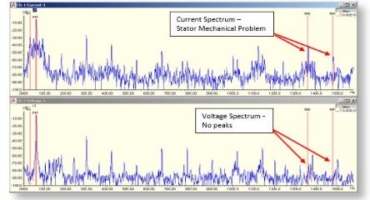

Stator Mechanical Faults Using Electrical Signature Analysis (ESA)

A stator mechanical fault is created when the stator core becomes loose within the motor frame, or if the windings are loose between the stator slots. A loose stator core or winding over a period of time will cause...

- Mark Koch

- ALL-TEST Pro, LLC

What Causes Electrical System Failures?

There are several contributors to electrical system failures: Loose connections, Moisture, Line disturbance, Defective or inadequate insulation...

- Paul Goodbody

- IRISS

Electric Motor Reliability Trifecta – Trending

For this tip we focus on qualitative trending of data. Remember trend is your friend and by qualitative trending we are talking about a change in the appearance of the data rather than an amplitude value change.....

- Noah Bethel

- PdMA Corporation

Challenges of Crane Monitoring

Monitoring the wheels and bearings of the overhead cranes is not easy. If we could detect poor lubrication and bearing defects, we could perform predictive maintenance and get ahead of the…

- Kris Deckers

- I-care Group

What Are the Root Causes of Wear in Industrial Machinery?

Taking appropriate action is almost impossible if you don’t know what the root cause of the failure is. Generally speaking, there are a handful of causes that are found to be responsible for most of the damage to – and failure of – industrial machinery...

- Chris Hansford

- Hansford Sensors

Alignment: Goal, Plan, Achieve

What do you want to achieve during alignment: precision, speed, or improved reliability of equipment? Remember, a goal without a plan is just a wish. When executing alignment, we need to properly plan the job...

- Dennis Swanepoel

- WearCheck

Leak-Testing Flanged Couplings

There are a lot of flanged couplings used in heat exchanger condenser systems. Finding vacuum or pressure leaks here is challenging

- Allan Rienstra

- SDT International

Maintenance Tips for Cooling Towers

View a few maintenance tips for protecting cooling towers and stopping any unplanned downtime with your equipment. Knowing the best detection technologies available today and how these can best be used, maintenance engineers can not only prevent failure but also significantly maximize machine uptime.

- Chris Hansford

- Hansford Sensors

Some Considerations When Using Ultrasound for Slow-Speed Systems

When using ultrasound for slow-speed systems, there are some things to consider. The first is our alarm levels. Slow-speed bearings will have a relatively…

- Christopher Hallum

- UE Systems Europe B.V.

- 1

- …

- 18

- 19

- 20

- 21

- 22

- …

- 42