Two Minute Tips

Cables for Handheld Vibration Analyzers and Portable Vibration Meters

Six considerations to select the right cables for vibration data collectors and hand held vibration meters..

- Peter Eitnier

- Wilcoxon Sensing Technologies

Why You Should Color-Code Your Lubrication Equipment

Paul Dufresne explains why it’s essential to implement a color chart system, also incorporating shapes for people who are colorblind…

- Paul Dufresne

- Reliability Playbook, in Partnership with Lubrication Engineers

Introducing Engineered Distribution Devices for Lubrication

In an engineered block system, the system operating sequence follows three steps: The lubricant is delivered to the divider valve block through a machine-mounted or hand-operated grease gun, then the positive displacement…

- Paul Dufresne

- Reliability Playbook, in Partnership with Lubrication Engineers

Why Filter Industrial Oil

As much as 70% of all premature machine failures can be attributed to contamination. To prevent these failures, it is important to purify the new oil as it comes into the facility and then keep it clean throughout its life. By establishing an ISO code cleanliness goal and maintaining it, you will extend the life of the oil and the equipment..

- Preston Rubottom

- Lubrication Engineers

A Quick Tip for Oil Storage

Why risk the effectiveness and lifespan of the lubricants that help maintain your machinery by leaving them susceptible to contamination? It’s time to get rid of the old methods that can allow water, dirt, and other particulates to contaminate your lubricants.

- John Sander

- Lubrication Engineers

What’s in Store for AI in the Next 5–10 Years?

Question: What’s in store for ai in the next 5–10 years? Mohan Amasa answers…

- Mohan Amasa

- AssetSense

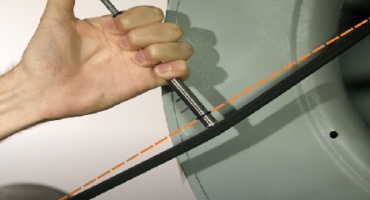

Why V-Belt Tension Gauges Matter

An often-overlooked precision maintenance tool is the V-belt tension gauge. Many maintenance technicians believe they can just go by “feeling” for what proper belt tension should be. In our Reliable Precision Maintenance (RPM) course, we often let mechanics tension the belts to what they “feel” is correct. Then we check the tension with a V-belt tension gauge. More times than not, we find that the belts are over-tensioned when going by “feel”.

- Stan Riddle

- Acoem USA

RCFA: Another Acronym but an Important One

There sure are a lot of acronyms around and it seems like new ones come out every day. Not sure about you, but I have a hard time keeping track of them. There are times when I attempt a conversation with someone, and they are spewing out so many acronyms it is hard to decipher just what they may be talking about...

- Stan Riddle

- Acoem USA

Interested in Learning about AI? Start Here

Artificial intelligence, and its role in industry, can no longer be ignored. So how do you even begin to learn about such a huge and confusing field? Matthew Moore, Dr. David Siegel, and Ed Spence discuss…

- Ed Spence

- The Machine Instrumentation Group

- 1

- …

- 3

- 4

- 5

- 6

- 7

- …

- 42