Two Minute Tips

Utilizing Phase to Confirm Machine Faults

It’s on all of the vibration fault charts, it’s taught in vibration classes, and it’s used for balancing – but how often is phase actually used by vibration analysts to confirm faults?

- James Otremba

- Acoem USA

Do Your Sensors Work for Your Processes? Observability is Key!

Imagine trying to measure the a 100° F temperature with a thermometer with a high value of 80° F, or your local police trying to catch speeding cars with a radar gun that only goes to 20 MPH. Both situations share the same problem, the sensor is not appropriate for their use!

- Jose Flores

- SensOS

Understanding How Laser Shaft Alignment Works

There are many root causes to vibration in the industrial sector. However, there are four that contribute up to 80%. Watch this tip to find out more about these root causes.

- Rich Merhige

- AME Solutions

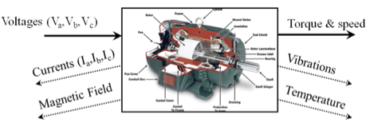

Motor Overload

Motor overloads occur when motors are drawing too much current. The main issue with excess current is that it creates heat which degrades the insulation surrounding the conductors that creates stator magnetic field.

- Bill Kruger

- ALL-TEST Pro

Extending the Life of Your Gear Oil

With consistent, accurate monitoring of the condition of your oil – whether in an engine, gearbox, circulating system or mainline power generation turbine – an oil analysis program can help you extend the life of the oil and protect the equipment.

- Nathan Walker

- Lubrication Engineers

Determining the Battery Life of a Wireless Vibration Sensor

Wireless vibration sensors have their place in a good reliability program and can really benefit the maintenance team’s ability to monitor machine health reliably.

- Alan McCall

- Sensoteq

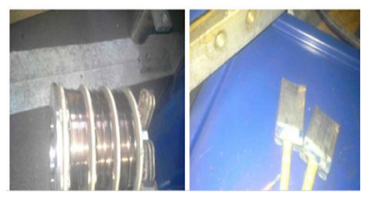

Wind Turbine DFIG Generator Slip Ring Defect

This case study shows how early detection of slip ring unit defect can result in a fast, inexpensive repair.

- Michael Hastings

- Brüel & Kjær Vibro (B&K Vibro)

Sampling Ammonia or Refrigerant Compressors

Monitoring acid level and contaminants, especially water and sediment are important factors to consider to maintain performance in reciprocating and screw compressors. When sampling ammonia, foaming is a regular issue that is encountered. In order to avoid this, the KPQ14NP has a locknut feature.

- Bernie Hall

- Checkfluid

Size Matters!

Designing a sensor for wireless condition monitoring is a complex balancing act between meeting performance requirements whilst adding the most value for the end user. The choice of technology becomes crucial when trying to optimize certain aspects of the design.

- David Procter

- Sensoteq

- 1

- …

- 5

- 6

- 7

- 8

- 9

- …

- 42