Webinars

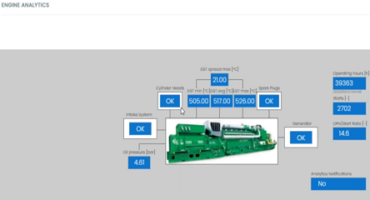

Gas Engine Reliability & Performance

In this training you will learn about engine smooth operation, Oil Management, Water Chemistry Analysis, how to get engine best performance in terms of higher electrical efficiency, smooth operation & lower maintenance cost.

- Noman Majeed

- Orient Energy Systems

Underwater Vibration Monitoring

This webinar is ideal for CBM practitioners in Water & Wastewater, Food & Beverage, and any other industries where the reliability of wet or underwater assets are important to plant production and operation.

- Peter Eitnier

- Wilcoxon Sensing Technologies

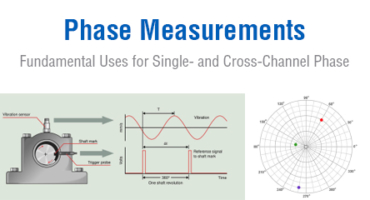

Phase Measurements-Fundamental Uses for Single and Cross-Channel Phase

Many machinery problems are easy to detect and to diagnose, but sometimes the issues can only reveal themselves upon more in-depth investigation. This presentation will show how this data is acquired, displayed, and used for diagnostics.

- Bob Martin

- IMI Sensors

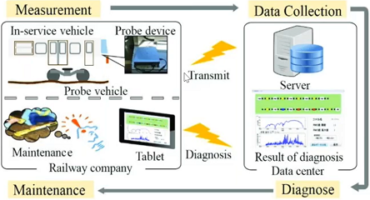

Rail Wheel Reliability Investigating Subsurface Damage Bifurcation Using Vibration Mapping

Rail is a costly industry prone to punctuality having issues like catastrophic failure, largely due to lack of accurate information. Locomotives are the lifeline & strength of a country or a state, they run like RBC and WBC in our blood vessels transmitting contents.

- Ashish Arora

- Institute of Noise & Vibration

How to Diagnose Different Failure Modes of Spherical Rolling Bearings Through Vibration Analysis

MOBIUS CONNECT WOW Middle East (Week of Webinars) Presents: How to Diagnose Different Failure Modes of Spherical Rolling Bearings Through Vibration Analysis.

- zaheer abbas

- PAE Solutions

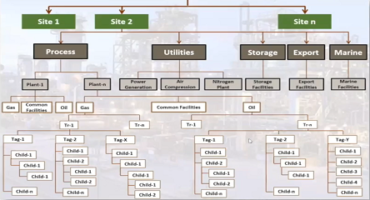

Maintenance Data Management

Maintenance (like many other functions) depends greatly on data. Maintenance data has always been a concern for most of the organizations due to many reasons and factors during the different phases of the asset life cycle.

- Ahmed Kotb

Industry 4.0 Technology

MOBIUS CONNECT WOW Middle East (Week of Webinars) Presents: Industry 4.0 Technology.

- Furqan Jahanzaeb

- Midas Safety

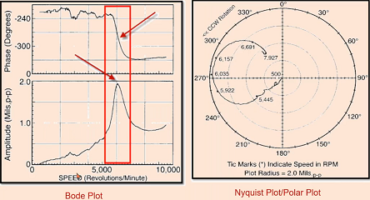

Identifying and Surmounting Resonance- The Silent Killer of Machine Uptime

Resonance in Industrial Plants, is a difficult problem to diagnose and at the same time, it’s a silent killer of machine uptime and Plant Reliability! The maintenance team probably won’t be asked to go out and correct the resonance problem. Instead, the Plant personnel will treat the symptoms of the resonance problem.

- Praveen Gupta

- Special Oilfield Services CO. L.L.C.

Trickling Down Corporate Goals Into Asset Strategies

Gone are the days when asset strategies were formulated on a standalone basis. Organizations are facing tough competition and a holistic and unified approach is required to tackle problems.

- Taha Bin Mahmood

- Empiricai

- 1

- …

- 11

- 12

- 13

- 14

- 15

- …

- 39