Webinars

An Insight into the Turbomachinery Condition Monitoring

Turbomachinery play a critical role in any process/manufacturing industry. To ensure the availability of these critical equipment, it is necessary to have an integrated condition monitoring covering vibration analysis, oil analysis, process parameters and an effective maintenance strategy. This webinar gives a deeper understanding of the condition monitoring of these turbomachinery.

- RAO VAMSIDHAR

- VIZAG STEEL

Power Generation Resilience Depends on On-site Oil Analysis to Ensure Availability

As we emerge from the global pandemic, power generation facilities face incredible challenges to maintain reliable power for their customers. Double digit increases in short supply specialty lubricants, rising costs, long lead times on parts and labor shortages mean downtime is more costly and unpredictable than ever. Facilities without CBM programs, and specifically on-site oil analysis capabilities, limit their options to detect and avoid operation downtime.

- Daniel Walsh

- AMETEK Spectro Scientific

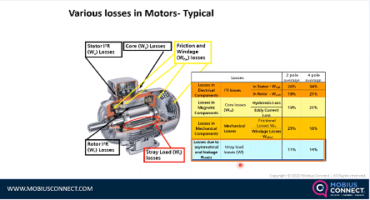

Improving Energy Efficiency in Induction Motors and Motor-Driven Systems

Standards and implementation strategies of Premium efficiency IE3 motors as per IS:12615/2018 (similar to IEC 60034-30) in Indian industries.

- Srinivasan Jeyaram

- Power House

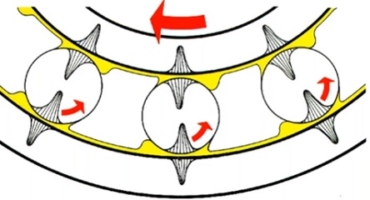

Optimizing Lubrication in Rolling Element Bearings

In this webinar, the author will discuss the benefits of implementing IIOT based remote monitoring strategy for essential Plant Assets and how this could enable a connected Asset Management framework that facilitates faster data collection, pan organizational visualization of the asset health and reliability metrics, ML/AI based automated diagnostics and moving the data not the people!

- Håkan Hedlund

- SPM Instrument AB

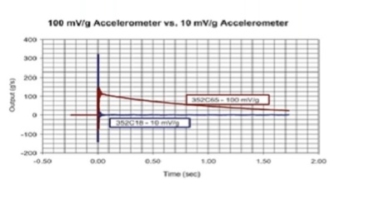

IoT Sensor Performance – Impact on Condition Monitoring

This talk will help you better understand key performance parameters of today’s wireless CBM systems, how they could impact the interpretation of vibration measurements and offer some guidance regarding sensor performance evaluation.

- Ed Spence

- The Machine Instrumentation Group

What a Playbook Can Do for Your Organization

This webinar will discuss the importance of having a lubrication playbook for your organization. Having a playbook will help the team visualize targets, understand continuous improvement model, and know what is needed to achieve goals and be successful.

- Paul Dufresne

- Reliability Playbook, in Partnership with Lubrication Engineers

Approaching Machines That Are New to You for Condition Based Maintenance

Whether you are an experienced vibration analyst or a novice, approaching machines that are new to you can present challenges. This presentation describes a sequential method that may be helpful in getting started in this process. Sometimes it’s nice to have defined steps to follow in order to get the data you need about the machine and it’s operation. By doing so, you will have a better chance of getting useful data that can lead to quicker and more refined diagnostics in the future.

- Bob Martin

- IMI Sensors

Developing a Balanced Approach to Contamination Control

In this impactful webinar, we will explain how “textbook” best practice can become reality through the application of a balanced approach to contamination control.

- Mark Barnes

- Des-Case

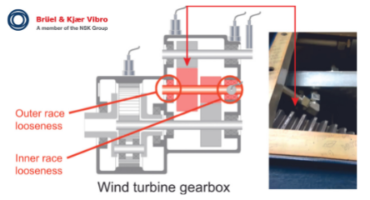

How to Detect and Diagnose Gearbox Bearing Looseness On a Wind Turbine

Case study on detecting and diagnosing gearbox bearing looseness on a wind turbine drive train.

- Jørgen Ellekjær

- Brüel & Kjær Vibro

- 1

- …

- 14

- 15

- 16

- 17

- 18

- …

- 39