Webinars

Specialty IEPE Sensors

An in-depth look at a variety of “specialty” IEPE vibration sensors including triaxial, high temperature, high voltage, and seismic sensors, and what makes them unique.

- Peter Eitnier

- Wilcoxon Sensing Technologies

Vibration, It’s Just Physics

In the presentation, we will go back to the basics and discuss the physics of vibration at a basic level. For example, the harmonic oscillator is one of the simplest concepts to understand yet governs most of vibration. At the same time, it is also the example that most physical concepts are applied to first from simple F=ma to complex electrodynamics problems. This presentation will be at the beginner’s level. No physics background needed. We will discuss where some of the basic tenets of vibration originate from and explore vibration from a whole new angle. If you are interested in vibration and want to see it in a new light this is for you.

- Jeff Hay

- RDI Technologies

Continuous Monitoring of Lubricated Assets: What Does It Really Tell Me?

While Industry 4.0 has brought real-time monitoring of assets to the forefront, what are we learning? In this webinar we’ll explore several case studies of continuously monitored assets. We’ll also look at case studies from vibration and ultrasound that show conditions that were undetected with route-based monitoring.

- Roy Giorgio

- AssetWatch

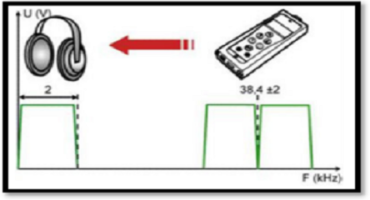

Ultrasound – A New Option for Permanent Monitoring

For 30 years, we have been producing customized ultrasonic transducers and sensors at our headquarters in Halle (Saale) / Germany with an output of currently 50.000 ultrasonic probes per year. We supply our customers with tailor-made and application specific solutions for a variety of industries and testing applications. Advancements in IIOT technology opened up the potential to include high-frequency ultrasound sensors into new and existing permanent mounted condition monitoring solutions.

- Brian Kavanagh

- SONOTEC

Sampling Towards A Cleaner, Greener Machine

Maintaining oil cleanliness is vital to the performance of lubricated equipment. Oil contamination accelerates the rate of component wear and leads to premature component failure. In a globally competitive market companies that can maintain machine reliability and uptime will be able to keep their costs at a more competitive level, see increased savings and run a greener operation. Discover how maintaining proper machine lubrication by reducing contamination and increasing oil cleanliness, through oil sampling, oil analysis, and filtering can help you achieve machine efficiency and improve your facility’s carbon footprint. Why? Efficient machines reduce your carbon footprint because they consume less energy and oil.

- Bernie Hall

- Checkfluid

Demystifying Ultrasound – A Showcase of Cool Animations and Simulations

An effective ultrasound program can reduce operating costs and detect a wide range of fault conditions in everything from rotating machinery to valves and steam traps, including vital electrical equipment and compressed air systems. But have you ever wondered how it works and why these assets generate ultrasound? Well, we have developed visually spectacular 3D animations and interactive simulations that we use in our training courses that make these topics easier to understand and fascinating to learn about - even for those who do not collect the data or run the program. So, get your team together and strap yourself in for this presentation from the founder of Mobius Institute and the designer of most of these training aids.

- Jason Tranter

- Mobius Institute

Gain Deep Insights into Bearing Health with Ultrasound

Before taking full advantage of ultrasonic technology, many of us go to great lengths to identify a failing condition in our anti-friction bearings. We look for either the smallest change in movement or a slight increase in surface temperature to tell us that something is not working properly. Could there be a more obvious measurement that will tell us that not only is something wrong, but more importantly, that will also help prevent the failure from occurring in the first place? Yes, and using ultrasonic equipment and analysis, it is so obvious! It is in the bearing’s name - Friction!

- Adrian Messer

- UE Systems

Fault Zone Series – Power Circuit Testing and Troubleshooting Considerations

High resistance connections, unbalanced voltages and currents, and a variety of other problems can occur from Power Circuit issues. From the Transformer through the distribution system to the stator connections at the motor, this presentation will perform a deep dive into testing and troubleshooting of the electric motor Power Circuit.

- Noah Bethel

- PdMA Corporation

Boost Lubrication Work Task Efficiency with Point of Care Oil Analysis

Using in-service oil analysis to improve machinery reliability is well understood since waiting for off-site results and diagnostics incurs delays that impact day-to-day, lubrication-related reliability tasks.

- Daniel Walsh

- AMETEK Spectro Scientific

- 1

- …

- 15

- 16

- 17

- 18

- 19

- …

- 39