Webinars

Towards Maintenance Excellence

Maintenance is a critical business function. It sustains your productive capacity, contributing to both fixed and variable costs. Well-maintained assets meet production commitments easily and at low risk, something that lenders and insurers like to see. Achieving maintenance excellence depends on many success factors such as leadership, strategic planning, skilled people, tactical activities, and continuous improvement. This presentation will explore the roadmap towards maintenance excellence.

- Ahmed Kotb

Integrating Multiple CBM Technologies into Your Reliability Program

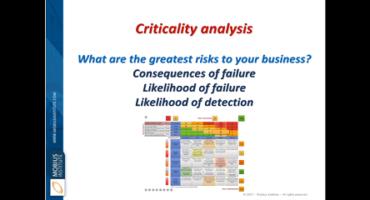

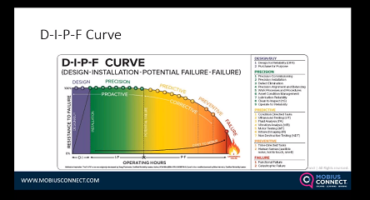

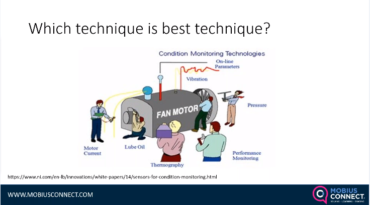

There are three ways to run a condition monitoring department. You can operate in separate groups, each with their own opinion of the health of the equipment based on their chosen technology. You can become more integrated where at least there is a shared view of the health of an asset. But the best approach, in the author's opinion, is where you take it one extra step: ensure the program is based on an analysis of the failure modes, ensure decisions are based on an assessment of the asset's criticality, ensure that the people receiving the information understand what to do with that information, and provide one clear statement of asset health that is accessible to everyone who needs it. This presentation will discuss the pros and cons of each approach and explain how to achieve the optimum state.

- Jason Tranter

- Mobius Institute

Condition Based Lubrication Best Practices Improving Overall Reliability

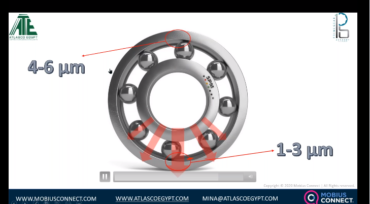

As the most common cause of bearing failure, lubrication is serious business. For many years, this “serious business” has been conducted in a way that makes perfect sense on the surface but in fact borders on being haphazard. Relying on time-based, periodic lubrication assumes bearings need to be greased at defined time periods will lead to the risk of under and over lubrication. By using ultrasound technology along with normal practices, you can combine standard time-based maintenance with condition-based predictive maintenance, gaining in the process both a clearer picture of what’s really going on in your machines to improved availability and reliability.

- Ahmed Moataz

- UE Systems Inc.

Why Do Bearings Fail?

Vibration Monitoring is the most commonly used condition monitoring method for rotating machines. Since resources are limited and we have a variety of Vibration Monitoring techniques, we have to ensure that our selection of VM technique is justifiable, hence it's required to follow a systematic procedures which are structured based on reasonably agreed criteria.

- Mina Soliman

- Noria Corporation

How to Ensure that your Vibration Monitoring Technique is Justifiable

Vibration Monitoring is the most commonly used condition monitoring method for rotating machines. Since resources are limited and we have a variety of Vibration Monitoring techniques, we have to ensure that our selection of VM technique is justifiable, hence it's required to follow a systematic procedures which are structured based on reasonably agreed criteria.

- Osama Hamed

- Uptime Intelligence

The Logical Fallacies in the Workplace (How to Know It and How to Avoid Doing It)

Learning Takeaways:

1. Know what the logical Fallacies are (A Manipulation Tool ) - How Logical Fallacy gets created and Why

2. Learn about the most 16 common Methods of logical fallacies (Each Method Description / Examples / How to Stop it )

3. The Tools to detect and Stop Logical Fallacies.

4. Why we turn to Logical fallacies to reach our goals instead of being direct and Honest

- Youssef Halim

- Noria Corporation

Performance Measurement to Support and Enhance Reliability and Asset Management

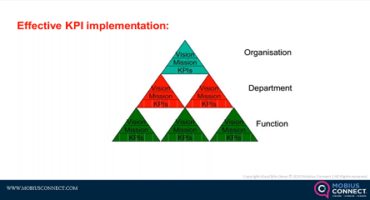

In this tutorial presentation, Alaa discusses how to use performance measurement to support and enhance reliability and asset management by presenting the basis and pillars for selecting, measuring, presenting and using KPIs that accurately reflect our future business performance; these measures allow focusing our priority items and not waste resources on non-value added initiatives or programs, as the strategic approach to management focuses on effectiveness and results.

- Alaa Omar

- Freelance

How Contamination Control is the Key to Success For Any Reliability Program

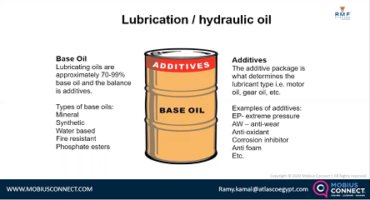

The presentation explores the topic of contamination control which is key to a proactive maintenance program. It defines contaminants and explains the damage caused by them in terms of chemical and physical changes to oil, as well as chemical attack or mechanical destruction of machine surfaces.

- Ramy Kamal

- Atlasco Egypt

Remote Reliability…Vision of the Future

This presentation will look at Remote Reliability solutions to short- and long-term issues involving employee availability, vendor and third-party support, network and data security, and asset criticality. We will be discussing hurdles to data acquisition, data analysis and data analytics.

- Noah Bethel

- PdMA Corporation

- 1

- …

- 19

- 20

- 21

- 22

- 23

- …

- 39