Webinars

Best Maintenance Practices for Control Fluid/FRF

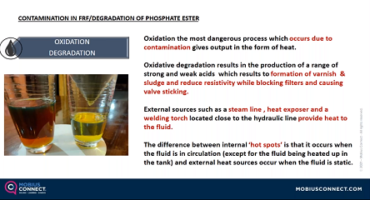

This is the most common and dangerous contaminate which frequently dictated the service live of FRF fluid. Uncontrolled generation of acidic products are harmful to the life and performance of phosphate esters.

- Yogesh Kumar

- Mobius

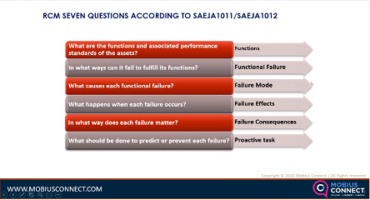

How to Develop the Maintenance Strategy Using the RCM/FMEA Driven Approach

Reliability Centered Maintenance is one of the tool in APM methodologies that looks into many evident and hidden failures of plant critical assets and give innovative technical solutions/PMs, which improves plant reliability and availability.

- Vinoth Kumar Subramani

- Machine Monitoring System - Center for Reliability Excellence

Evolution of Vibration Analysis into the Asset Reliability Transformation

This presentation will begin with a brief history of Mobius Institute with a focus on why we exist. Then Jason Tranter, the founder of Mobius, will discuss how vibration analysis, and the other condition monitoring technologies all deliver tremendous value. Every organization's goal must be to eliminate the reasons why failure occurs, not just detect the failures themselves. Improving reliability has proven to be terribly difficult, and that is why the Asset Reliability Transformation [ART] exists. Jason will discuss his frustration with the way most people have had to approach their reliability improvement initiative and how ART resolves all those issues.

- Jason Tranter

- Mobius Institute

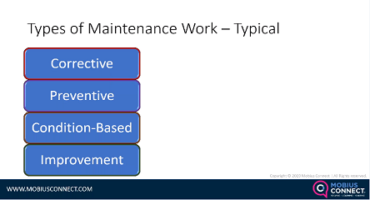

Basics of Reliability Management

Asset-intensive organizations today constantly endeavor to optimize the risks, costs and performance of their assets across their lifecycle to deliver value from their Asset Management in meeting their Business Objectives. The O&M Phases of Asset Lifecycle comprises development and management of Asset Strategies followed by their execution in Work Management and analysis for continual improvement.

- Sundar N.P.

- Stellar InnoStrat Consulting

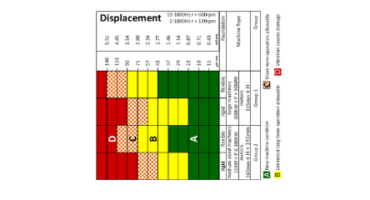

Discussion on The Application of ISO Vibration Standards ISO 10816-1, 10816-3 and 20816-1

We take this opportunity to introduce a panel of vibration experts to discuss their experience in utilising these standards; their benefits, limitations, and the considerations to make them most effective in different applications and industries.

- RAO VAMSIDHAR

- VIZAG STEEL

Lowering Your TCO by Focusing on Reliability

Learn how you can reduce your total cost of lubricants by keeping them dry and clean.

- Preston Rubottom

- Lubrication Engineers

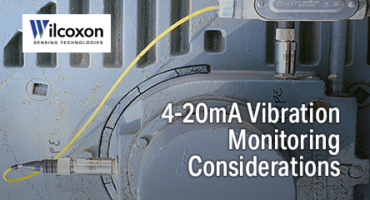

4-20mA Vibration Monitoring Considerations

Discussion focusing on vibration monitoring using 4-20mA products. Loop powered sensors, vibration transmitters, display and alarm modules will be covered as well as their most important product selection considerations and various combination possibilities.

- Peter Eitnier

- Wilcoxon Sensing Technologies

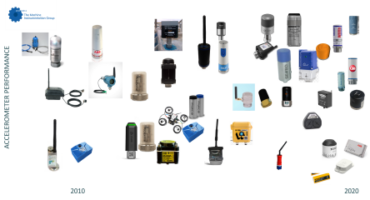

MEMS Accelerometers – Technology Review and Implications for CBM

In this session we will compare and contrast MEMS accelerometer technology with legacy PZT, discussing the implications for IIoT and CBM applications in general. We will demonstrate how MEMS performance improvements made over the last 5 years not only supports overalls trending but also enables bearing fault detection and diagnostics. With a better understanding of the underlying sensor technology strengths and limitations, we will also show how MEMS accelerometer performance positioning data suggests using caution when selecting wireless IIoT solutions for your assets.

- Ed Spence

- The Machine Instrumentation Group

Streamlining the PdM Process using MCA Motor Testing

Streamlining the PdM process using MCA motor testing” presents brief discussion of Predictive Maintenance and how to incorporate the various MCA technologies to identify motor faults. Identifies the types of faults each MCA identifies. Discuss TVS, “static”, “dynamic”, ground fault & phase comparison tests. Discuss which types of faults the various MCA technologies identify.

- Bill Kruger

- ALL-TEST Pro

- 1

- …

- 20

- 21

- 22

- 23

- 24

- …

- 39