Webinars

Leveraging Color-Changing Thermochromics for Electrical Inspections

In industrial electrical systems, intermittent overheating can be difficult to detect. Thermographic inspections can only pick up overtemperature events that are active at the time of the inspection. This means that high temperatures can remain undetected for some time, making them a persistent and unseen fire risk. The only way to determine if your system has intermittent overheating is to monitor your equipment 24/7.

- Mark Paul

- IRISS, Inc.

Online Condition Monitoring Systems: Latest Developments and Deployment Use-Case

Traditionally portable sensor-based condition monitoring systems haven proven their effectiveness over last few decades in managing risks in the critical assets operation and optimization of the maintenance activities. The online condition monitoring systems are becoming more affordable and effective in recent years in terms of transient events detection, data acquisition safety, fault tracking and proactive maintenance of critical assets.

- Tarun Motwani

- Noble Engineering Services

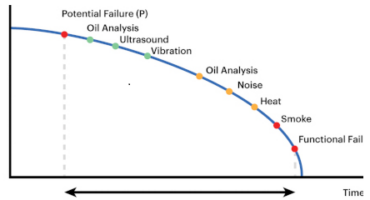

Moving from Reactive to Condition Based Maintenance – Common Failings and How to Avoid Them

Successfully embedding a move from a reactive state to a proactive or even data driven state is a common aim across industry, but rarely is it achieved in a way that sustains the benefits that we all know it can. In this webinar, I will talk about the common reasons for failure and share our experiences such that those embarking on a similar journey can set themselves up for success.

- Chris Bates

- Binnies

Continuous Electric Motor Testing

Retiring employees, pandemic work from home response, or just advances in technology and a desire for improved reliability are all legitimate reasons for the surge in interest for permanently installed electric motor test equipment with remote access.

- Noah Bethel

- PdMA Corporation

Model-Based Machine Health Algorithms

KCF Technologies is combining standardized machine health sensor installation with both AI-generated and human-validated cases of various machine faults to build asset-specific models for assets like pumps, fans, electric motors, gearboxes, etc. to automatically identify machine faults.

- Dave Kraige

- KCF Technologies, Inc.

Water Contamination in Lubricants

In this presentation, we will discuss types of water contamination, effects on the health of lubricants and machines, how we can control them and how we can measure these in a lab.

- Hina Sarfraz

- Lube Tribology Pvt Limited

Optimizing Pump Performance Leveraging Model-Based ESA Analysis for Effective Pump Curve Monitoring

In this webinar, we will explore the significance of pump performance monitoring and the implementations of model-based ESA analysis to enhance efficiency and reliability in various industrial applications.

- Tumay Karaver

- Artesis Technology Systems

Bearing Precision Lubrication and CBM using Vibration Monitoring and Ultrasound Detection

Under- and over-lubrication contributes to 40-70% of bearing failures. Precision lubrication can be achieved with ultrasound analysis and supported with vibration root cause analysis. Ultrasound monitoring can be used to hear and analyze the friction index of each bearing, indicate the precise amount of lubrication required, and extend the life of the bearing.

- Peter Eitnier

- Wilcoxon Sensing Technologies

Unlocking Opportunities: Harnessing Thermal Imaging for Enhanced Maintenance Solutions

This webinar will introduce attendees to the range of portable thermal imaging hardware and software solutions currently offered by FLIR, particularly in relation to their application in Condition Based Maintenance operations.

- Jason Cargill

- FLIR Systems Ltd

- 1

- 2

- 3

- 4

- 5

- …

- 39