White Papers

Diagnosis of Hidden Faults at an Early Stage

Artesis Predictive Maintenance Solutions are applied in a variety of industries and applications for improved manufacturing plant reliability and availability. One of these applications is Positive Displacement Blowers, where Artesis is used most frequently.

- Tumay Karaver

- Artesis Technology Systems

Predictive Maintenance in Water and Wastewater Facilities

Rapid urbanization in the last 50 years and its effects are felt intensely. Undoubtedly, one of the most important processes of urbanization is water and wastewater management.

- Tumay Karaver

- Artesis Technology Systems

Maximizing Pump Reliability Through Precision Lubrication

From pumps to compressors, turbines to gearboxes, equipment reliability is vital to maintain a competitive advantage. Layer in the exceptionally high downtime costs of certain units that can exceed $1MM a day, the harsh operating environment (typically outside), and the long turnaround cycles that can extend to 3-5 years and it all adds up to a significant challenge.

- Mark Barnes

- Des-Case

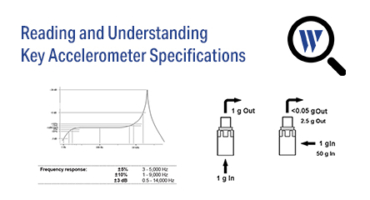

Reading and Understanding Key Accelerometer Specifications

There are many ways to evaluate an IEPE (Integrated Electronic PiezoElectric) sensor, or accelerometer, either on its own merits or in comparison to similar competitive models found on the market. The most obvious is a paper comparison, using the spec sheet as a guide. Other options include acquiring the contending sensors and putting them to the test or obtaining word-of-mouth inputs, each of which will likely result in a different conclusion. The most common starting point, however, is a spec sheet appraisal.

- Peter Eitnier

- Wilcoxon Sensing Technologies

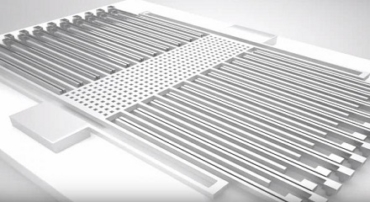

Why MEMS Accelerometers Are Becoming the Designer’s Best Choice for CbM Applications

A small number of semiconductor manufacturers have overcome the noise, bandwidth and g-Range shortcomings commonly associated with MEMS sensors used in Condition-based Monitoring (CbM) by producing several medium and high-performance MEMS vibration sensors with the latter being comparable to piezo accelerometers.

- Chris Murphy

- Analog Devices, Inc

New Single-Pair Ethernet: High-Quality Asset Health Insights and Power on Two Wires for Condition Monitoring Applications

Condition monitoring applications continue to grow in importance, as equipment manufacturers look to increase asset utilization with real-time monitoring of equipment, extend equipment lifespans, and increase throughput by utilizing predictive maintenance techniques to reduce maintenance costs and asset downtime..

- Maurice O'Brien

- Analog Devices, Inc

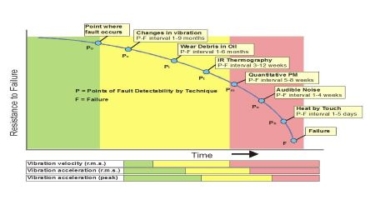

Switching Strategies: Moving to Condition Based Maintenance

Balancing cost reduction and efficiency improvement targets is a common source of frustration for maintenance and engineering managers. For facilities that operate continuously with no window for unplanned shutdowns, poor reliability and availability of machinery is far more serious, but even in factories with regular opportunities for maintenance, recovery can still be expensive and time consuming.

- AVT Reliability

The Wearable for Machine Health: Condition-Based Monitoring

Condition-based monitoring (CbM) is the Industry 4.0 equivalent of wearable fitness devices. With the explosion of connectivity comes the opportunity to observe the physical world like never before and to see physical processes in action, in real time, in fine detail. In industrial....

- Stuart Servis

- Analog Devices

iCOMOX: Connectivity Options and Application

The Intelligent Condition Monitoring Box also known as iCOMOX is an open-source sensor fusion platform designed for Condition-based Monitoring (CbM) applications. The iCOMOX can measure vibration, sound, temperature, and magnetic field displacement. This device can...

- Richard Matsick

- Analog Devices, Inc

- 1

- 2