White Papers

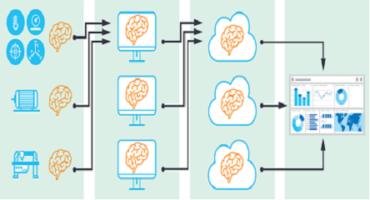

Embedded Sensor Platform with AI Algorithms—Locally from Big Data to Smart Data

Industry 4.0 applications generate a huge volume of complex data—big data. This naturally increases the potential for generating added value along the entire value chain. Only with relevant, high quality, and useful data—smart data—can the associated economic potential be unfolded...

- Dzianis Lukashevich

- ADI

SONAPHONE DataSuite Software: Management of Ultrasonic Data in a Power Station

This white paper will present and shed more light on how ultrasonic technology is used and the benefits offered by DataSuite in the context of a power station...

- Steffen Moeck

- SONOTEC

Technology Based Crane Monitoring and Diagnostics

Overhead cranes are often a single source cause of downtime in any manufacturing facility, especially when discussing those performing services in a steel mill’s melt shop. Often, these assets do not have redundancy that would allow for one to be taken....

- Stephen Bailey

- IVC Technologies

The Trifecta of Motor Maintenance

Using the same concept of a trifecta (three factors for success), this article provides companies with the winning strategies of motor maintenance, focusing on the three reliability tasks for electric motor testing and the order in which they should be applied.

- Noah Bethel

- PdMA Corporation

Torsional Issues: Stop Guessing and Measure the Problems Directly

Failure mechanisms such as misalignment, balance, or lubrication issues can cause machinery failure. Many of these problems can be identified using standard non-destructive testing (NDT) methods including vibration analysis, infrared thermography, and tribology....

- Trent Martz

- IVC Technologies

5 InsightCM™ Features for Remote Diagnostics

Reliability engineers can’t be in two places at once. But when assets from two different plants are raising concern, how does the engineer figure out which one is more likely to contribute to an outage? Remote diagnostics help maintenance teams decide where to deploy valuable resources like subject matter experts, troubleshooting equipment, and spares.......

- Brett Burger

- National Instruments

10 Steps for Implementing IoT in Your Industrial Space

Organizations may be tempted to throw IIoT-enhanced devices and software at the wall to see what sticks. This may be an option, but it’s not conducive to a successful maintenance program rollout...

- Frederic Baudart

- Fluke

Cracking the ISO Code to Lubricant Cleanliness

So what does it really mean to increase lubricant cleanliness? We read various articles and textbooks that talk about how increasing the cleanliness of an in-service oil will increase the life of a component and the lubricant, but how do we make that happen...

- Mark Barnes

- Des-Case

The Importance of Good Maintenance Practices Based on Condition Monitoring

Pruftechnik’s service team was contacted by our client when the online vibration monitoring system in their machine’s dryer inlet fan reached an alarm value of 12mm/sec rms. After our team conducted thorough analysis of the data, they suspected that the severe vibration was caused by...

- Shoukat Ali Izhar

- PRUFTECHNIK S.E.A. Pte Ltd

- 1

- 2

- 3

- 4

- 5

- 6