Two Minute Tips

Avoiding Bearing Failure Through Proper Grease Management

I’m a hard worker. I get my hands dirty. More than 60% of bearing failures are due to lubrication, and grease failures contribute more than the oil. Whenever the bearings are replaced in the housing, mostly the housing is fully packed with the grease without keeping empty space and it starts operating the bearing after the housing end cover is sealed.

Immediately after few minutes of operating the bearing, the temperature inside the bearing starts uncontrollably rising and will continue to operate at a higher temperature until the grease property is lost. Bearings will start to fail prematurely due to failure of lubricant film formation as oil viscosity drops due to an increase in temperature.

How does the temperature inside the bearing increase when grease is fully packed without empty space? The main purpose of lubricant inside the bearing is to form a thin oil film between the rolling element contact and the raceways so that metal-to-metal contact is avoided.

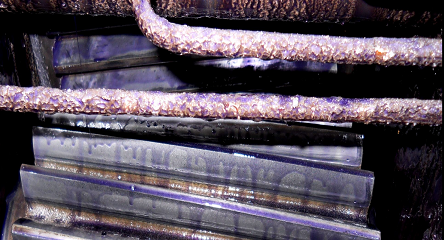

Each rolling element inside the bearing is separated by a spacer or cage, which provides space to fill and accommodate grease and to lubricate the rolling elements while running. If excess grease is packed inside the bearing without empty space, individual rolling element speed will be 4-5 times higher than the shaft speed, leading to grease churning in which the bearing has to work much harder to push through the excess grease resulting in grease degradation and overheating.

Never pack the bearing housings FULLY up to the neck and always ensure only 30-40% grease volume is sufficient to lubricate the bearing and can wait until the relubrication interval starts. After all, bearings need only OPTIMIZED lubricant, not OVER or UNDER, and follow the 0.005xDxB ( D= outer diameter, B= width) formula for the relubrication interval or as recommended by OEM.

Never use hands and cotton waste for bearing grease filling, as this is more dangerous to your bearing due to contamination entry. When oil film thickness is 15 micro inch, human hair is 3000 micro inch and fingerprint is 500 micro inches, a cotton waste fiber can be a much higher threat to bearings.

Let’s start working CLEAN & SMARTER and not DIRTY & HARDER.