About the Author

Nilay is an experienced condition monitoring engineer and ISO certified vibrations analyst with a history of working in the power, mining & metals industry.

READ FULL BIOVibration Readings:

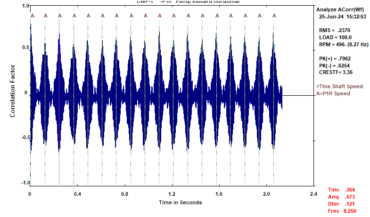

CWP-1 – Cooling water pump-1 (25-Jun-24) PARM = OVERALL

P1H=Pump Inboard Horizontal 3.468 1.196 mm/Sec 2.272 190 %+

P1P=Pump Inboard Horz Peakvue .312 .106 G-s .206 194 %

P1V=Pump Inboard Vertical 3.553 1.446 mm/Sec 2.107 146 %+

P1A=Pump Inboard Axial 2.320 2.040 mm/Sec .280 14

P2H=Pump Outboard Horizontal 1.773 1.202 mm/Sec .570 47

P2P=Pump Outboard Horz Peakvue .552 .213 G-s .339 159 %

P2V=Pump Outboard Vertical 2.090 1.773 mm/Sec .317 18

P2A=Pump Outboard Axial 2.066 1.659 mm/Sec .406 24

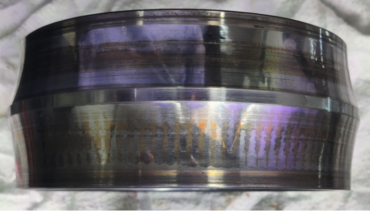

Inner race having marks observed.

Rolling element having marks.

Outer race: having pitting marks observed. And outer surface having pitting marks observed.

Nilay is an experienced condition monitoring engineer and ISO certified vibrations analyst with a history of working in the power, mining & metals industry.

READ FULL BIO

Nice catch.

In addition, I suggest use of Ultrasound technology for bearing inspection. This will identify the problem in an early stage, resulting in early maintenance/repair, and will avoid problem to reach this state.

indeed. will do the same.

You got the bearing fault but did you the proper ISO fault level? It looks like it was called early. ISO usually indicates that 0.25in/sec or 6mm/sec. I use the time between discovery and confirmation to call to let maintenance know there is a fault so they can order parts and get prepared and then coordinate with operations for an optimal shutdown window.

Dear Ty Huffman,

Running RPM is 496 only and if we wait till 6 mm/sec level then it’s too late for such speed. even at this vibration and impact level bearing also get 70-degree temperature and usually temperature range is 50-55 degree.