About the Author

Offering 12 years of experience, I joined Al Jouf Cement Saudi Arabia as a Mechanical Maintenance Engineer.

I am currently serving as a condition monitoring engineer and mechanical planner.

Phase analysis is a key tool in checking the health of machines by looking at their vibrations. It measures how the timing of vibration signals line up with each other, usually from different parts of a machine. This helps find problems like parts not lining

up right, balance issues, parts being loose, or gear problems. This analysis helps spot certain mechanical problems not visible through just looking at signal strength. By understanding the movement relation, maintenance teams can more accurately find the source of vibration problems. This precise diagnosis is key to fixing machines efficiently, cutting downtime, and making machines last longer.

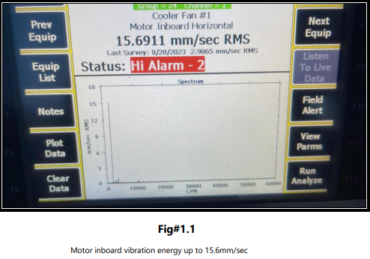

– In our case this overhung cooler fan was generating high radial vibrations in Motor

inboard only Fig#1.1

FFT Spectrum:

Measures Taken:

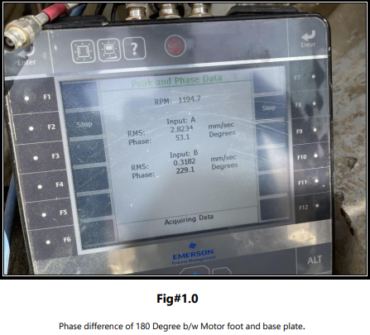

After all actions vibration levels didn’t decrease, then finally phase analysis was performed on all points.

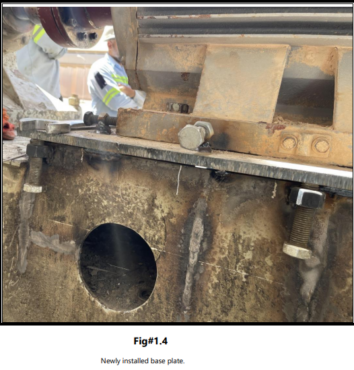

Phase difference of 180 degrees Fig#1.0 between Motor foot and base raised concern of soft foot or worn out base plate, later on it was decided to replace the base plate Fig#1.4 which resulted in the drastic drop of vibration levels.

Offering 12 years of experience, I joined Al Jouf Cement Saudi Arabia as a Mechanical Maintenance Engineer.

I am currently serving as a condition monitoring engineer and mechanical planner.

Phase is critical in the analysis process to determine how the machine is vibrating. Once we understand this, we know how to apply the proper corrective and precision maintenance tasks.