Alignment + Balancing

Join Us at Reliable Plant Conference 2025!

The Reliable Plant Conference & Exhibition, co-located with the Machinery Lubrication Conference & Exhibition, is a 4-day event dedicated to the latest trends and tactics in maintenance and reliability. With expert-led learning sessions, access to cutting-edge tools and technologies offered by over 100 exhibitors, and powerful networking experiences, this is a can’t-miss event for anyone looking to transform their maintenance strategy.

- Noria Corporation

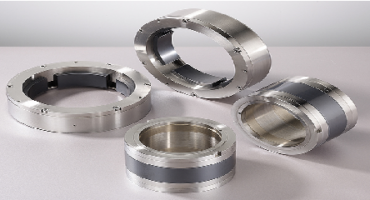

Understanding Cross-Coupled Forces in Journal Bearings

Before explaining the cross-coupled forces generated by the journal bearing, it is worth reviewing and understanding some key concepts on how the journal is located within the bearing and what forces are acting on the journal.

- Ahmed Rezk

- Tabreed

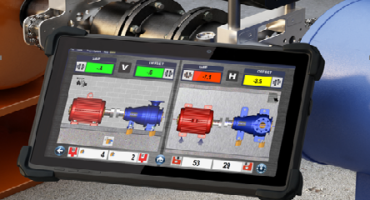

Accuracy and Repeatability in Shaft Alignment

Terry Southall, Brand and Distribution Manager of Hamar Laser Instruments, discusses methods such as relying on a Window-Based Platform and using super-linear Position Sensing Detector (PSD) sensors and more to ensure maximum accuracy in laser shaft alignment.

- Terry Southall

- Hamar Laser Instruments, Inc.

How to Properly Evaluate Laser Shaft Alignment Kits

Selecting the right laser shaft alignment kit is critical for maintaining the reliability, efficiency, and performance of rotating machinery. With a wide range of systems available, choosing the best tool for your needs requires a thorough evaluation of key factors, including accuracy, repeatability, ease of use, durability, longevity, and cost-effectiveness.

- Terry Southall

- Hamar Laser Instruments, Inc.

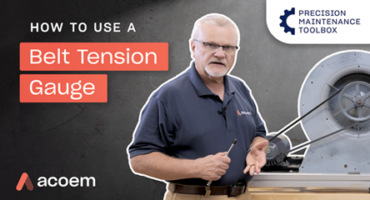

Precision Maintenance Toolbox Series

Acoem's Precision Maintenance Toolbox Video Series is a comprehensive resource designed to help maintenance professionals improve their technical skills and knowledge. Hosted by Acoem technical trainer Stan Riddle, the series provides step-by-step guidance on essential tools and techniques used in industrial maintenance.

- ACOEM USA

- Acoem USA

Shaft Alignment 101: Runout

Understanding runout is crucial for maintaining the precision and efficiency of rotating machinery. Runout refers to the deviation from true circularity or concentricity in a rotating object, such as a shaft or a cylindrical part.

- ACOEM USA

- Acoem USA

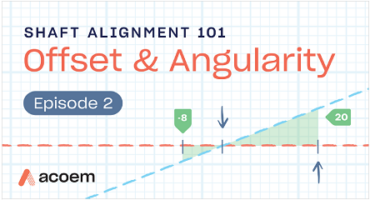

Shaft Alignment 101: Offset & Angularity

Shaft alignment is a critical aspect of machinery maintenance, with the stationary shaft and movable shaft needing to be precisely aligned to avoid potential failures. In a typical setup, the movable shaft is adjusted relative to the stationary shaft to ensure alignment within machinery tolerances.

- ACOEM USA

- Acoem USA

Shaft Alignment 101: The Basics

In this video, you’ll learn the intricacies of precision alignment, exploring the measurement, calculation, and adjustment processes necessary to achieve optimal shaft alignment.

- ACOEM USA

- Acoem USA

Introduction To Wireless Sensors In Condition Monitoring

Condition monitoring is by no means a new concept in industry. In fact, it is so widely regarded as a best practice, that it becomes commonplace in more industries each year. With this increase in awareness, we have seen an influx of options over the years...

- John Waldron

- Acoem USA

- 1

- 2

- 3

- …

- 12