Lubrication

Episode 2: Lubrication Condition Monitoring (LCM)

Tune in to Episode 02 now, where we review the 3 essential components to your Lubrication Condition Monitoring program.

- Aaron German

- simatec

Proper Lubrication Can Increase Profits and Decrease Emissions

A 2004 US EPA study stated that “synthetic engine and drive train lubricants can improve fuel economy by around 3%, saving nearly 500 gallons in a year.” There are many ways to measure energy usage in your plant. Imagine the effect a lubrication program can have…

- John Sander

- Lubrication Engineers

How Lubrication Reduces Energy Consumption

Machines use a lot of energy overcoming friction. John Sander discusses different types of lubricants and explains how they help your machines…

- John Sander

- Lubrication Engineers

Episode 1: Introduction to simatec

Welcome to the first episode of the simatalk series. simatalk is an educational show that provides viewers with tips and tricks for their lubrication condition monitoring programs.

Tune in now to learn more!

- Aaron German

- simatec

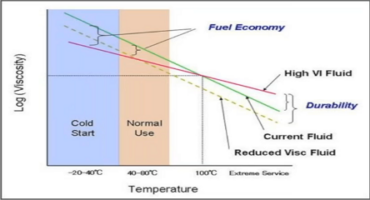

The Significance of Lubricant Viscosity

There have been significant changes in the lubrication industry recently, in which we have seen improvements in performance due to lower viscosity, resulting in decreased fluid friction…

- John Sander

- Lubrication Engineers

Industry’s Role in the Global Energy Outlook

One big reason we perform monitoring and maintenance is to reduce the amount of energy consumed by a machine, and by the plant as a whole. John Sander of Lubrication Engineers gives an overview of the global energy outlook…

- John Sander

- Lubrication Engineers

How Improved Lubrication Practices Helped This Air Compressor Save Energy

John Sander discusses how lubrication practices have saved costs and reduced emissions in an air compressor, a knitting plant, and a glass and ceramic producer…

- John Sander

- Lubrication Engineers

How Grease Works and Saves You Energy

Greases are thickened lubricants, meaning they do not flow. So how does grease reduce friction? John Sander explains…

- John Sander

- Lubrication Engineers

Perform a Lubrication Consolidation Program

We know the 5 R’s of effective lubrication: the right product, in the right location, in the right amount, at the right time, and in the right condition. But how many of you treat lube oil and grease as an asset…

- Paul Dufresne

- Reliability Playbook, in Partnership with Lubrication Engineers

- 1

- 2

- 3

- 4

- …

- 14