Motor Testing

The Damaging Effect Water Can Have on Your Motors

Moisture: good for plants, never good for electric motors.

- Noah Bethel

- PdMA Corporation

Insulation- Todd and Noah Show

In this episode, we talk about the Charlie Brown fault zone: Insulation. Back in the 1840's, one of the first forms of insulation which was developed to prevent electricity from getting to a person or ground, was glass.

- Todd Gunderson Noah Bethel

- PdMA Corporation

Introduction to Motors- Todd and Noah Show

Welcome to episode one of the Todd and Noah Show! We will be taking the mystery out of electric motors throughout this podcast to help industry professionals.

- Todd Gunderson Noah Bethel

- PdMA Corporation

The Power Circuit- Todd and Noah Show

Today, we discuss ways in which the power circuit can help save on efficiency. Because energy costs are so high, we want to be efficient.

- Todd Gunderson Noah Bethel

- PdMA Corporation

Case Study: Loose Power Connections

A conveyor motor was tested during an annual inspection that operated in the part transfer line. Annual testing for the plant was conducted during a scheduled shut down. Using the automated

routes mode of the & MCA™ Software.

- Bill Kruger

- ALL-TEST Pro

The Importance of Power Quality- Todd and Noah Show

Today, we talk about IEEEs (Institute of Electrical and Electronic Engineers), our favorite standard of reference when talking about establishing alarms and limits.

- Todd Gunderson Noah Bethel

- PdMA Corporation

The Importance of Predictive Maintenance

As early as the 1960’s, many companies realized that by routinely monitoring the operating condition of rotating equipment it is possible to obtain an advanced warning of operational or other problems that would impact continued efficient operation. This early warning provides time to remove the machine from operation and affect minor repairs and adjustments before catastrophic failure occurs.

- Bill Kruger

- ALL-TEST Pro

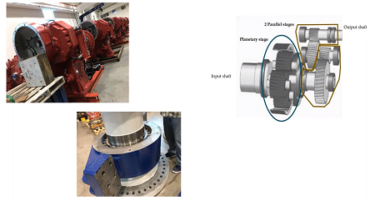

Performing Electrical Signature Analysis on Wind Turbines

Howard Penrose gives an overview on the motors and gearboxes found in wind turbines and goes through case study examples involving electrical signature analysis…

- Howard Penrose

- MotorDoc LLC

Service Factor of Motor’s & Cables

The motor and associated cabling have service factors to consider for your process environment as does the equipment you use to monitor your uptime. Variables to consider when replacing your motor and cabling are operating environment temperatures, conditions of process (wet, dry, dirty, etc.) and the process load.

- Bill Kruger

- ALL-TEST Pro

- 1

- …

- 3

- 4

- 5

- 6

- 7

- …

- 21