Motor Testing

Beginner’s Guide To Motor Testing

Motors when installed play a critical role in many manufacturing efforts. Businesses in all industries rely on machines to drive profits, so testing these motors ensures your investments are available for demanding tasks.

- Mark Koch

- ALL-TEST Pro, LLC

Developing a Successful Motor Maintenance Program – Part 1

What makes your electric motor maintenance program a winner? Answer: A good Quality Control program from cradle to grave along with Trending Data and Troubleshooting. Watch this video to see how one part of the program, Quality Control, helps you reach your goal of a winning program in your facility.

- Noah Bethel

- PdMA Corporation

Preview the 2021 SMRP Annual Conference!

The Society for Maintenance and Reliability Professionals (SMRP) is preparing to welcome attendees for its 29th Annual Conference. Hear from SMRP Executive Director Erin Erickson about what's in store for attendees at this year's event.

- SMRP

How To Check Motor Winding Resistance On Single & Three-Phase Motors

Motor Circuit Analysis™ (MCA™) is a test method that determines the true state of health of 3 phase & single-phase electrical motors. MCA™ checks the motors coils, rotor, connections, and more. MCA™ can verify ac motor winding resistance as well as dc motor resistance and determine state of health.

- Mark Koch

- ALL-TEST Pro, LLC

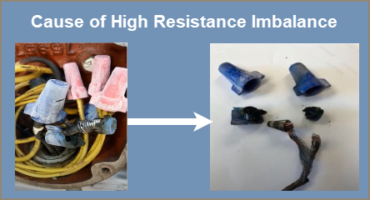

How High Resistance Imbalances Can Damage Your Electric Motors

A small, but critical, motor in a pulp and paper mill exhibits a changing and rising resistive imbalance indicating a power circuit anomaly. If the motor fails, the loss of production costs could be up to $20,000 per hour. Follow along as they test and investigate the problem.

- Noah Bethel

- PdMA Corporation

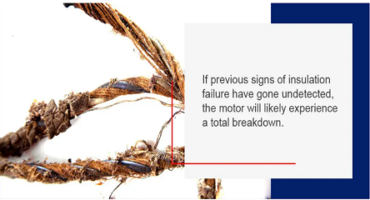

Electrical Insulation Failure

Electrical Insulation is used to direct current through a desired path and prevent it from flowing where it is not desired. Proper electrical insulation is critical to an electric motor’s performance and longevity. Insulation breakdown is one of the most frequent causes of electric motor failure. In electric generators, for instance, 56% of failures originate from electrical insulation damage.

- Mark Koch

- ALL-TEST Pro, LLC

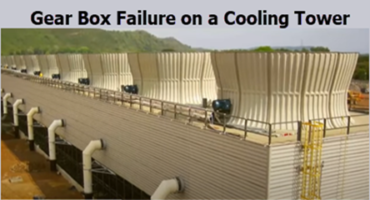

Gear Box Failure on Cooling Tower Induction Motor Fan

The large motors in this power plant are attached to a gear box, which is attached to a cooling fan inside the cooling tower. All components are enclosed inside a shroud, making a visual inspection difficult and costly. A knocking noise, possibly coming from inside the shroud, was detected. But was it the motor or the gear box? Watch the video to learn how the problem was analyzed without disassembling the shroud.

- Noah Bethel

- PdMA Corporation

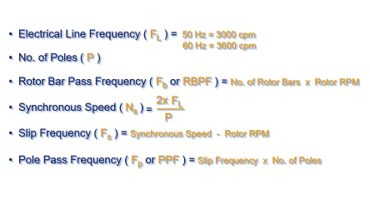

Electrical Frequencies Calculation and AC Motor Faults Patterns. Part 1

The fault diagnosis of induction motors, being probably the most common drivers used for industrial machinery plays an important role to reduce the catastrophic failures and production lost tonnage.

- Pawel Lecinski

- CMRP

Trending DC Field Inductance in an Aluminum Mill Coil Motor

A critical 600 hp motor was redesigned to 750 hp and was running at 900 hp, which created excessive heat. To avoid catastrophic failure, motor was tested every three weeks. The Megohmmeter reading was normal, so how did they know there was a problem? Watch this video and learn.

- Noah Bethel

- PdMA Corporation

- 1

- …

- 5

- 6

- 7

- 8

- 9

- …

- 21