Oil Analysis + Wear Particle

Which Is the Best Bearing Fault Detection Technique?

Now, this is a tricky question to answer…

- Jason Tranter

- Mobius Institute

Is It Important to Use Wear Particle Analysis?

If your oil analysis includes particle counting and can detect metallic elements...

- Jason Tranter

- Mobius Institute

Hydra Main Propulsion Gearbox

Once upon a time, there was a ship called the Hydra. They were suspicious that the gears or bearings in the main gearbox were failing and asked a vibration analyst to perform a test. The analyst turned to me for help...

- Jason Tranter

- Mobius Institute

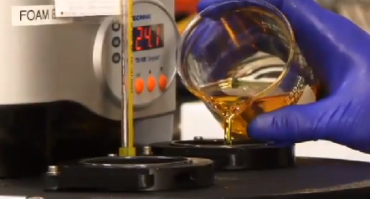

Karl Fischer Test

Water can seriously damage the lubricating properties of oil and promote component corrosion...

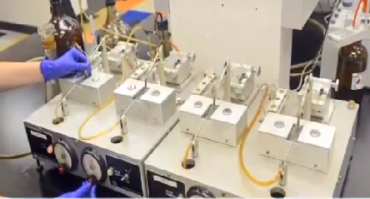

Analytical Ferrography

Analytical ferrography is an extremely valuable tool for examining wear particles...

CMMS – Friend or Foe?

In every good maintenance program, there needs to be a place to store a history of problems found and actions taken if we are to learn from our experiences and continuously improve...

- Paul Dufresne

- Reliability Playbook, in Partnership with Lubrication Engineers

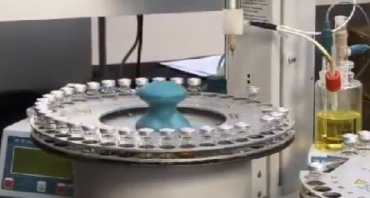

Introduction to Elemental Spectroscopy

Elemental spectroscopy measures in-service fluid samples for wear metals, additives, and contaminants...

Prediction of Vibrational Fatigue on Bolted Joint Interfaces Using CAE

Vibrational fatigue is the failure of a material under cyclic loading caused by forced vibration. An excited structure responds at its natural frequencies, resulting in a dynamic stress load...

- Ameer Ambavaram

- Mercury Marine

- 1

- …

- 8

- 9

- 10

- 11