Oil Analysis + Wear Particle

Differences in Wear Quantification Used in Wear Debris Analysis Techniques

Primarily, we have three types of wear quantification techniques that are usually seen in various industrial oil analysis reports...

- KNV Subrahmanyam

- Single Peak Lube Technologies

The Importance of Oil Sampling on a Regular Basis

Routine oil sampling is the key to a successful maintenance program. Oil testing provides...

- Evan Zabawski

- TestOil

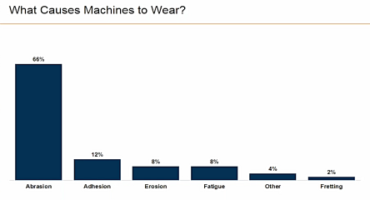

What Causes Machines to Wear?

In this quick two minute tip, we discuss the factors that cause machines to wear...

- Mark Barnes

- Des-Case

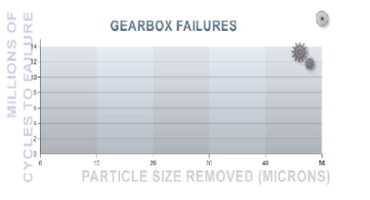

Gearbox Oil Essentials

Industrial gearboxes are expected to perform under conditions of high heat and heavy loads; and in environments often contaminated with dirt...

- John Sander

- Lubrication Engineers

What Size Particles Do the Most Harm?

For many people, the key test to determine if there are damaging particles in the oil is to flied between their fingers or look at an oil sample. It is amazing how much you miss. This video will explain which particles do the most damage. Spoiler alert, they are very, very small...

- Jason Tranter

- Mobius Institute

Oil Analysis Trending vs. Alarm Limits

Many static alarm limits are based on statistical analysis of a common grouping of machines under similar operating conditions...

- Evan Zabawski

- TestOil

Why Don’t My Oil Analysis Results Correlate?

A common issue related to report interpretation deals with a perceived necessity for the results from two or more different tests to indicate the same potential problem...

- Evan Zabawski

- TestOil

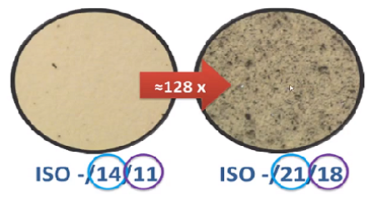

How Do You Interpret Particle Count Readings?

It’s a very common test to look at the cleanliness of oil or hydraulic fluid, and it’s based on this standard called ISO 4406...

- Jason Tranter

- Mobius Institute

- 1

- …

- 6

- 7

- 8

- 9

- 10

- 11