Vibration Analysis

Sensors for speed measurements

Choosing the right speed sensor for turbomachinery is of crucial importance for an accurate and reliable measurement. After all, the signal of the sensor is the input for an overspeed protection system. A faulty sensor leads to an unreliable input signal, which has a negative influence on the accuracy and reliability of the protection system.

- Istec International

Preview the 2021 SMRP Annual Conference!

The Society for Maintenance and Reliability Professionals (SMRP) is preparing to welcome attendees for its 29th Annual Conference. Hear from SMRP Executive Director Erin Erickson about what's in store for attendees at this year's event.

- SMRP

Techniques for Sensor Validation and Troubleshooting

Validating and troubleshooting vibration sensor setup and performance is an important part of ensuring an effective vibration monitoring system. If a sensor is not working correctly, or if a sensor is not mapped to the correct measurement point, the accuracy of the information is compromised...

- Tom LaRocque

- Wilcoxon

Important Vibration Analysis Tips You Need to Know

In the last 20 years the industry has improved predictive maintenance processes and the tools used to perform it. In particular, vibration analysis technology has evolved to unimaginable levels.

What is vibration analysis? And more importantly, what do you need to know to start learning about it? Well, I invite you to read this article to explore it with me.

- Dr. Thierry Erbessd

- Erbessd Instruments

What Is Machine Vibration?

Everyone agrees that vibration data provides information about the condition of the machine and the operation of the equipment, but what exactly is machine vibration? We can say it is an oscillation wherein the…

- Ron Newman

- PRUFTECHNIK

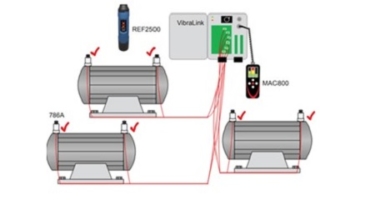

Online Monitoring Systems | How to choose?

Online monitoring is the process of utilizing permanently mounted sensors to regularly check the condition of a machine. Online monitoring should consist of more than just vibration sensors. Given there are many different failure modes it is best to utilize a variety of sensor types to monitor the necessary variable to ensure early warning of failure.

- Dr. M. David Howard

- Erbessd Instruments

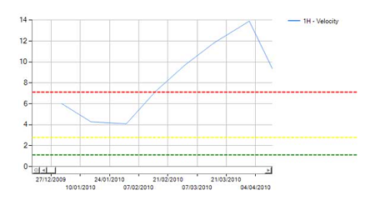

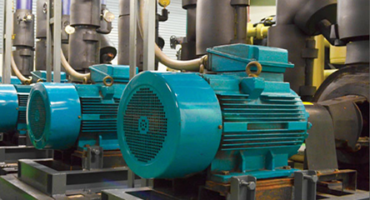

Warning Signs of Pump Cavitation

Pumps are critical pieces of equipment in a large variety of industrial settings. Although they are routinely monitored as part of a facility’s CBM program, the data captured in this way isn’t always enough to identify the signs of early-stage pump cavitation. Vibration data can provide valuable insight into the pump’s condition, and with the right monitoring setup can help you identify developing cavitation before serious damage or failure occurs.

- Elise Brannon

- Wilcoxon Sensing Technologies

The Importance of Balancing a Turbo

Internal combustion engines use turbochargers as a way to output more power. Some turbocharger impellers can reach speeds up to 300,000 rpm.

Unbalance at high speed generates vibration that will not only reduce the engine performance, but may eventually cause permanent damage to the whole system. Needless to say, turbo balancing machines are important in maintenance activities for turbocharger systems to work in optimal conditions.

- Dr. M. David Howard

- Erbessd Instruments

Resonance & Natural Frequency

Have you ever tried to balance a fan and its vibration won’t go down? No matter what you do, do you know what Resonance is?

3 Tips to diagnose Resonance and 6 ways to correct it below.

- Dr. Thierry Erbessd

- Erbessd Instruments

- 1

- …

- 8

- 9

- 10

- 11

- 12

- …

- 28