Vibration Analysis

Key Features for a Vibration Analyst

For more complex analysis, analysts require more advanced tools to better diagnose issues. Playing the TWF as an audio file is a good way of listening to the vibration to potentially hear knocking, pinging or high frequency whistling, denoting a problem to further diagnose, as if you were actually beside the machine.

- Alan McCall

- Sensoteq

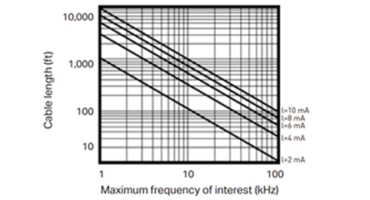

Maximum Cable Length for Vibration Sensors

A vibration sensor produces an AC voltage dependent on the vibration signal being measured. As such, it’s subject to all the limits of AC signals. Long cable runs are likely to introduce enough capacitance into the sensor circuit to cause distortion, which makes being able to calculate cable length limits very important..

- Elise Brannon

- Wilcoxon Sensing Technologies

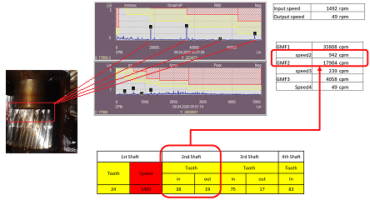

GMF Calculation and Gearbox Problems Detection

Gearbox defects can be identified with a quite high accuracy using vibration analysis. This is because the fact the most common defect frequencies are the fundamental Gear Mesh Frequency (GMF) and its harmonics (such 2x GMF, 3x GMF) which can easily detected.

- Pawel Lecinski

- CMRP

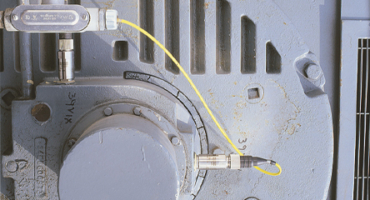

4-20 mA vs. IEPE Vibration Sensors for Process Control Systems

With process control systems, it’s simple (and smart) to incorporate vibration data into an existing monitoring program. Either loop-powered 4-20 mA sensors, which output a direct 4-20 mA signal, or IEPE sensors, which output dynamic data that can be converted into an acceptable process signal, can be used..

- Elise Brannon

- Wilcoxon Sensing Technologies

How Many Averages

Signal processing in the FFT analyzer or vibration data collector includes averaging. How many averages should you take to reduce noise and produce an accurate vibration spectrum?

- Jason Tranter

- Mobius Institute

Peak Hold Averaging

Averaging - understanding peak hold averaging in the FFT analyzer, signal processing, noise reduction, FFT analysis in vibration data collector FFT analyzer, number of averages.

- Jason Tranter

- Mobius Institute

Spectral Resolution-Averaging

Averaging and lines of resolution in FFT analyzer vibration spectrum. How many averages to take, data collection time in spectrum analyzer vibration data collector.

- Jason Tranter

- Mobius Institute

Analyzer Settings

Fmax, lines of resolution, averages, and units in the FFT analyzer. The video describes important settings in the vibration data collector and FFT vibration analyzer when signal processing to create the vibration spectrum

- Jason Tranter

- Mobius Institute

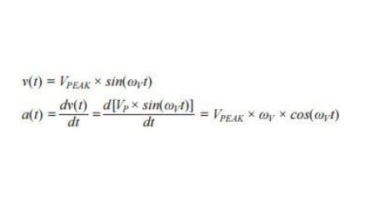

MEMS Vibration Sensing: Velocity to Acceleration

MEMS accelerometers are just now coming of age as vibration sensors in modern condition monitoring (CM) systems. Recent expansion of capability in measurement range, bandwidth, and resolution is enabling new concepts and system architectures...

- Mark Looney

- Analog Devices

- 1

- …

- 10

- 11

- 12

- 13

- 14

- …

- 28