Vibration Analysis

How to Mount a Vibration Sensor

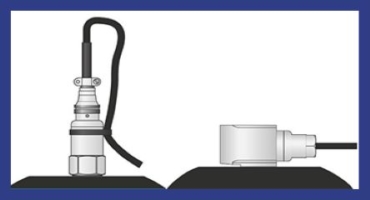

The mounting of a vibration sensor directly impacts its performance. Incorrect mounting may give readings that relate not only to a change in conditions but also to...

- Chris Hansford

- Hansford Sensors

How to Ensure Successful Acceleration Enveloping

Acceleration enveloping is the sophisticated signal processing technique that helps to pinpoint bearing failure at an early stage. Below is a guide of how to successfully implement it...

- Chris Hansford

- Hansford Sensors

Installing Wireless Monitoring on Overhead Cranes

Compared to most applications, wireless monitoring of overhead cranes is quite challenging. We need high-speed sampling for fault detection. And because this is a low-speed application…

- Kris Deckers

- I-care Group

Vibration Analysis report of Broken/Cracked Rotor Bar

In March of 2016, the vibration for Turbo Blower 2 was normal, but the motor temperature had increased. Ten days later, however, it was running rough with periodic noise...

- Muhammad Trendo

- Indah Kiat Pulp & Paper Perawang

Challenges of Crane Monitoring

Monitoring the wheels and bearings of the overhead cranes is not easy. If we could detect poor lubrication and bearing defects, we could perform predictive maintenance and get ahead of the…

- Kris Deckers

- I-care Group

What Are the Root Causes of Wear in Industrial Machinery?

Taking appropriate action is almost impossible if you don’t know what the root cause of the failure is. Generally speaking, there are a handful of causes that are found to be responsible for most of the damage to – and failure of – industrial machinery...

- Chris Hansford

- Hansford Sensors

Mining the Potential of Vibration Monitoring

The last couple of years have been tough for many mining and quarrying companies, with erratic commodity prices, mineral grade decline and increasingly strict government regulation being just some of the issues that have hit profitability...

- Chris Hansford

- Hansford Sensors

PF Mill Motor Electrical Fault

This case involves a motor that has just been serviced. During the last six months, the motor showed elevato

- Salah Attia

- ALS Industrial

Maintenance Tips for Cooling Towers

View a few maintenance tips for protecting cooling towers and stopping any unplanned downtime with your equipment. Knowing the best detection technologies available today and how these can best be used, maintenance engineers can not only prevent failure but also significantly maximize machine uptime.

- Chris Hansford

- Hansford Sensors

- 1

- …

- 13

- 14

- 15

- 16

- 17

- …

- 28