Vibration Analysis

Case Study: Inner Race and Shaft Rotational Looseness

Upon inspection, marking was done with white marker between inner race and shaft to confirm the looseness. On the next visit, the mark was clearly moved...

- Muhammad Muneeb Babar

- Al Jouf Cement Company

Dominant 1X

If you have a single channel analyzer and there is not any opportunity to use another tool like cross phase, how do you scientifically analyze this issue and identify the fault(s)?

- Wael Salman

- Dietsmann France

Striking the Balance: Automated vs. Manual Diagnosis

Vibration data is, at its heart, complex. Analysts require many years of experience in both reviewing data and a high level of understanding of the machinery...

- David Procter

- Sensoteq

When to go Wireless, and When Not

When it comes to condition monitoring, wireless technology is becoming ubiquitous for sensing applications. But many analysts still have a tried and tested portable monitor in their arsenal, so this begs the question, why should wireless sensors be used, and is there still a place for the more traditional route-based option?

- David Procter

- Sensoteq

The Scope and Application of Electrical Signature Analysis in Windpower

Electrical Signature Analysis (ESA) was initially developed at Oak Ridge National Labs (ORNL) in the 1980s as a method for evaluating bearings and gears in motor operated valves in the nuclear power industry. In 1992, the technology was licensed into general industry for applications in utilities and commercial applications...

- Howard Penrose

- MotorDoc LLC

Exploring Vibration Analysis Technologies

In the realm of industrial maintenance, understanding the health of machinery is paramount. One of the most effective tools in this pursuit is Vibration Analysis technology. By examining the oscillations and vibrations of machinery, it’s possible to detect early signs of wear, misalignment, and other issues before they escalate into costly failures. In this article, we will delve into the different facets of Vibration Analysis technology and compare Handheld/Portable, Wireless, and Continuous Online Condition Monitoring solutions.

- Florian Buder

- ACOEM

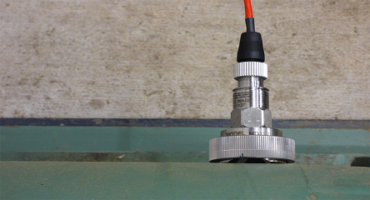

Cable Protections for Permanently Installed Accelerometers

Today, we tune in with subject matter expert, Peter Eitnier from Wilcoxon Sensing Technologies to discuss Cable Protection for Permanently Installed Accelerometers. Selecting the right cable for permanently installed accelerometers is critical to ensuring the integrity of your vibration sensor data. It's also important to protect the cable for long service life, often in harsh environments. Today, Peter will break down how to carefully consider these factors when purchasing a sensor and cable....

- Peter Eitnier

- Wilcoxon Sensing Technologies

Sensor Fusion: The Path to Proactive Plant Maintenance and Operational Excellence

A powerful approach for improving plant maintenance programs is the integration of multiple sensing technologies to improve coverage of machines and different failure modes. This can be further complemented by effective analysis of the data from all the different sources. When using multiple sensors like this, it is called Sensor Fusion...

- Alan McCall

- Sensoteq

Cables for Handheld Vibration Analyzers and Portable Vibration Meters

Six considerations to select the right cables for vibration data collectors and hand held vibration meters..

- Peter Eitnier

- Wilcoxon Sensing Technologies

- 1

- 2

- 3

- 4

- 5

- …

- 28