Vibration Analysis

Machine Learning, Sensors, and AI- What’s the Scoop?

Today, we sit down with Anil Lakhlan from Sensoteq to discuss machine learning and AI technology, along with sensors and vibration analysis.

- Anil Lakhlan

- Sensoteq

Erratic Vibration Behavior in a Steam Turbine

This machine had shown erratic shaft and pedestal vibration since its inception – the vibration would increase and decrease, predominantly at 1x…

- RAO VAMSIDHAR

- VIZAG STEEL

Two Peculiar Cases of Misalignment

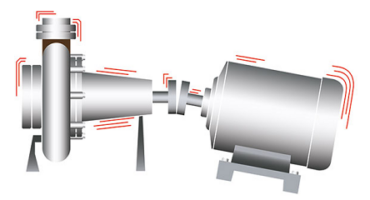

Misalignment causes a lot of problems, but it doesn’t always make itself known through vibration. Vamsidhar Rao explains two cases…

- RAO VAMSIDHAR

- VIZAG STEEL

Abnormal 1x Vibration Problem in an Oxygen Compressor

After a major overhaul of an oxygen compressor, 1x vibration was observed in the L.P. discharge bearing. We tried several remedies without success, such as changing the oil pressure and temperature, balancing the rotor…

- RAO VAMSIDHAR

- VIZAG STEEL

Intrinsically Safe Vibrations Sensors Enable Condition Monitoring in Hazardous Locations

Vibration monitoring is essential for predictive maintenance of rotating machinery. This is no less true in hazardous locations, and certified sensors designed for these locations are readily available. Below, we’ll focus on Intrinsically Safe sensors, which meet the requirements for hazardous locations found in chemical processing facilities, refineries, mills, and other facilities where flammable materials are processed or handled...

- Peter Eitnier

- Wilcoxon Sensing Technologies

Digitalizing Traditional Sensor Technologies with IO-Link

Learn how IO-Link has changed the smart sensor industry, enabling you to adapt your current sensors to offer secure digital output, customize your system, and make smarter, data-driven decisions—all while reducing the costs of streamlining data.

- Bob Martin

- IMI Sensors

Commercial and Industrial Power System Losses and Mitigation through Neutral and Ground

Even in discussions related to power harmonics most engineers, let alone reliability and energy professionals, understand the potential losses through the system. When it comes to harmonic content in neutral and ground in single and three phase systems, and the related losses, there has been limited attention...

- Howard Penrose

- MotorDoc LLC

Avoiding Unplanned Downtime: Online Monitor of Critical Bearings

Keeping a close eye on the condition of critical equipment is fundamental in any industrial facility. When critical bearings fail, it almost always leads to unplanned downtime and interrupted production process, costing companies thousands in production loses. In this case study we will look at how an online monitoring solution using ultrasonic sensors was able to detect an issue on a critical bearing before it turned into a big problem.

- Peter Boon

- UE Systems Inc.

Does Your Maintenance Program Need Maintenance?

A “good” maintenance program involves keeping equipment in peak condition and mitigating failure. Getting to this result takes the proper balance of strategies, people, and resources. Mark Frogley explains...

- Mark Frogley

- Acoem USA

- 1

- 2

- 3

- 4

- 5

- 6

- …

- 28