Vibration Analysis

Motion Amplification Case Study: Structural Looseness

This case study features a convection oven fan used in the customer's production process. Multiple welds and other repairs were made prior to the inspection. A service team was called in to balance the fan, but with Motion Amplification it quickly became clear that there was a serious structural issue.

- Andrew Dougherty

- RDI Technologies

Underwater Vibration Sensor Selection

Underwater vibration monitoring can be accomplished through various methods and sensor styles. Peter Eitnier discusses some of these methods in more depth.

- Peter Eitnier

- Wilcoxon Sensing Technologies

Gear Induced Vibration Study With HD ENV Technology

Learn about HD ENV technology and how it allows early detection of gear faults in a gear box coupled with a gas turbine for energy generation.

- Ettore Di Pasquale

- SPM Instrument Srl

Case Study: Cooling Tower Vibration Monitoring

Cooling towers are a critical component in many process facilities and contain several pieces of rotating machinery that contribute to their operation. Motors, gearboxes, fans and shafts require vibration monitoring to provide technicians with early warning signs of impending failures that could lead to catastrophic breakdowns.

- Peter Eitnier

- Wilcoxon Sensing Technologies

Using Baseline for Analysis

When you measure on your machine, the results may vary even if no defects are present. That is just normal behavior. This video will discuss how using baselines in analysis can be beneficial in keeping machines healthy.

- Stefan Furness

- SPM Instrument AB

Accelerometer Maximum Cable Length Calculator

When cables between the power supply and the accelerometer are short, less than 100 feet or 30 meters, circuit capacitance usually has no significant effect on the vibration data signals. Long cables may introduce sufficient capacitance into the sensor circuit to allow vibration signal distortion and produce spurious signals.

- Peter Eitnier

- Wilcoxon Sensing Technologies

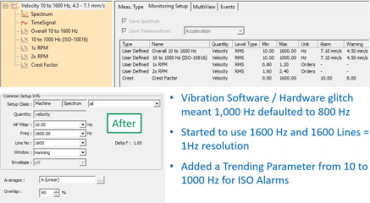

Why Use 1000Hz-800Hz Lines When You Have a Choice?

Most people use 1000Hz as the standard setting, but nobody asks why. Why not make your life easier by having 1Hz resolution rather than 1.25 or 0.625 Hz? Lines is ALWAYS a selected value but FMax can be user defined or selectable.

- Matthew Moore

- Moore Reliability Limited

Accelerometer mounting techniques impact the accuracy of vibration measurements

Guidance for vibration practitioners on evaluating and determining the ideal location and mounting method of vibration sensors for each machine and vibration source to be monitored. Specific guidance is given for permanent accelerometer installations, route-based data collection, high-frequency vibrations, low-clearance locations, and electrical isolation.

- Peter Eitnier

- Wilcoxon Sensing Technologies

Time Waveforms Take Us Inside the Machine

Time Waveforms give us a summary of all of the vibration that it records during the time that it is recording. It tells us exactly what happens from moment to moment. Jason Tranter will explain more in detail what happens based on the information that is recorded.

- Jason Tranter

- Mobius Institute

- 1

- …

- 5

- 6

- 7

- 8

- 9

- …

- 28