Two Minute Tips

Don’t Forget to Lubricate Your Couplings on Spare Machines

Don’t Forget to Lubricate Your Couplings on Spare Machines

Nowadays, many different coupling designs are available for specific purposes. Solid and rigid couplings do not require lubrication. Others, such as geared, chain, and grid, need lubrication for optimum performance.

What happens to those spare machinery couplings that must be re-lubricated? Do you think it is important to check the lubricant condition, as well as when the last preventive maintenance was done on them, before starting the machine up? The answer is an absolute YES!

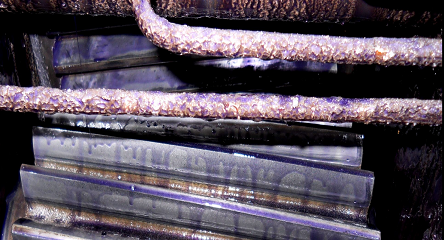

As you can see in the images below, this is what happened with a grid coupling (motor-centrifugal pump arrangement) in a petrochemical plant.

The machine was only in service for three hours before failure. It had been a spare for a long time, affected by contamination and environmental phenomena. Also, the plant’s maintenance practices were reactive instead of preventive/predictive, so this item was neglected.

To keep spares in good condition, it is crucial to have good communication and coordination between the different departments involved in equipment performance. As technicians, engineers and leaders, we are responsible for this and our goal is to systematically achieve excellence.

Takeaways:

- Verify the lubricant condition before starting up a machine that has sat on the shelf for a long time.

- Verify when the last preventive maintenance was done and which tasks were performed.

- Re-lubricate the coupling (if applicable) at least once a year.

- Predictive techniques could prevent downtime for this kind of failure.