Professionals in the industries of manufacturing, power generation and water rely on electric motors to complete their objectives. To remain efficient, it is essential that motor-based systems stay in peak operating condition. A sudden motor failure can occur when you least expect it, so understanding procedures for fast motor testing will help you maximize uptime.

Just because an electric motor sounds like it is working does not mean all components of the system are dependable. Equipment operators have the ability to test electric motors quickly.

Reasons to Test Motors on a Routine Basis

Electric motors power systems that drive profits for your business. Testing motors is relatively simple. Finding issues with an electric motor before a complete system shutdown occurs ensures your ability to continue meeting deadlines.

All electric motors experience wear and tear due to excess vibration and heat. Select industries are forced to run equipment 24/7/365. Understanding your motor’s state of health and mitigating problems is essential. Easy motor testing will determine the condition of your equipment in a few minutes.

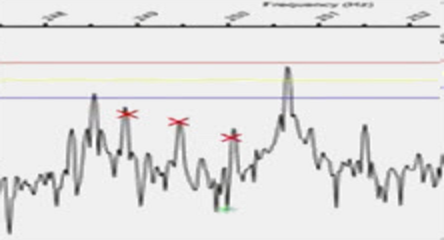

Motor Circuit Analysis (MCA™) Testing

Motor Circuit Analysis (MCA™) performs a series of de-energized tests locally at the motor or more conveniently from Motor Control Center (MCC). These patented deenergized tests determine the motor health by exercising the motors winding and groundwall insulation system. Faults in the motor’s rotor, cable, controller or stator are quickly and easily evaluated and reported using onscreen instructions and instantly displays the motors condition using easy to understand results as good, bad, or a warning.

MCA™ can also be used for troubleshooting motor system trips or faults which saves hours of guesswork trying to separate mechanical from electrical faults or more in-depth trouble shooting by quickly evaluating and identifying faults in the entire electrical portion of the motor system.

Test Electric Motors Quickly With MCA™

Initial MCA™ testing is performed from the MCC. This evaluates all connections, cabling and other components between the test point and the motor itself. If a fault or faults are detected from the MCC simply retest progressively closer to the motor to locate and isolate the fault.

The following sections tell you more about common motor problems and what testing devices can communicate about your equipment:

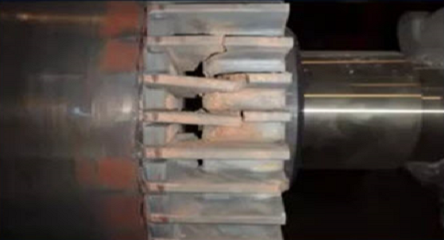

1. Winding Faults

It has been estimated that 37% of all induction motor failures are the result of winding faults. Motor winding faults occur because of faults in the insulation system. Insulation faults are caused by contamination, wear, age, or thermal degradation and generally begin with very small changes in the chemical makeup of the insulating material and get worse over time. Early identification and correction of these faults will prevent unscheduled faults, downtime and prevent catastrophic failure and mitigate any damage caused by a winding failure.

2. Resistance Problems

Electrical resistance between motor windings is measured in ohms. Ohmmeters are useful tools for determining resistance of the conductors, but it is not the conductors that fail in electrical equipment, rather, it is the insulation surrounding the conductors making up the coils or windings. Ohmmeters apply a known voltage to a circuit and measure the amount of current created by the resistance of the circuit. The resistance of the winding is determined by the type of the conducting material, the diameter and length of the conductor, but provides “zero” indication of the condition of the insulation surrounding the conductor. However, this measurement will locate open windings, loose connections, or severe faults in the insulating material where the resistance of the insulation between conductors falls below the resistance of the conductor around the fault.

For example, 22-gauge copper wire has a resistance of 0.019 ohms per foot, if the circumference of a coil is 3 feet, the resistance of 1 turn is 0.057 Ω. If each coil has 70 turns the resistance of each coil would be 3.99 Ω. If the three-phase stator has 24 coils each phase would have 8 coils in series each phase would have 31.92 Ω. Therefore if 2 turns were directly shorted, the resistance of the phase would be 31.863 Ω. This is usually not in the accuracy range of most ohmmeters.

Since the main characteristic of current is that it takes the path of least resistance of insulation, the conductors must be degraded until it is < 0.057Ω before the current will short cut around the coil and be able to be detected using the resistance measurement. In this example, 0.057/31.92 is 0.18% for 22-gauge wire regardless of wire size and the percentages will remain the same. However, the resistance measurement is very effective indication of loose connections, open coils, or possible complete shorts between phases.