Subbu, how did you start your career?

Way back in the year 2000 after completing my Mechanical Engineering Diploma, I started working in machinery lubricant analysis with an oil analysis testing company in India. Initially, I was been exposed to see the lubrication-related operations of various manufacturing sectors like cement, steel, refineries, petrochemical and various other industries which gave me a good exposure to understand the machinery operational conditions of different industrial segments. I also used to collect lube oil samples from critical industrial equipment where I would analyze their condition in the laboratory.

What do you think some of the most important needs in the industry are?

In my opinion, the current industry needs a lot of reliability-based training that can help optimize equipment performance and improve the safety and reliability conditions of critical machinery components. To me, these trainings should consist of all aspects of reliability goals, condition monitoring aspects and lubrication related excellence etc.

What equipment do you prefer to use and why?

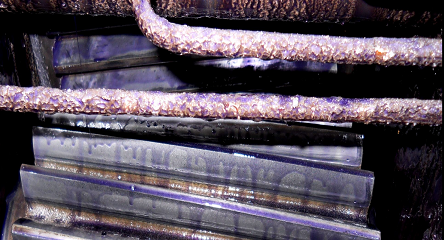

I see ferrography analysis is still considered to be an exceptional testing and my personal experience is that ferrography technology has to be implemented In addition to the traditional oil analysis techniques like spectroscopy etc. Ferrography analysis instruments are my preference because ferrography is a machine wear debris monitoring technology, which helps us to understand the potential equipment component failure modes in the early stages of failure. Additionally I would prefer using hand held FT-IR instruments which gives very good information on lubricant health condition and contamination.

What existing technologies look the most promising?

In addition to the existing condition monitoring practices, I think that there is great opportunity for growth with oil condition and Machine wear identification sensors, ultrasound analysis for better lubrication practices, and advanced machinery lubrication practices.

What are the biggest trends in the industry that you see these days?

Lubrication management practices are a fast-growing segment because companies have started realizing the potential savings opportunities it provides in improving the machine reliability and reducing the lubricants consumption ratios.

I foresee improvements in the wireless vibration monitoring technologies is the next generation of monitoring. Wireless monitoring is also a segment where people are looking to reduce human intervention as safety related aspects are most priority in major industries.

What are your goals as you continue your journey in the condition monitoring industry?

As an oil analysis and lubrication professional, my goal is to keep learning about the new developments in machinery lubrication, and Industry 4.0 requirements for machinery lubrication as focal point. To be able to provide more support to the readers of prestigious publications like CBM CONNECT, Machinery Lubrication India etc.