In the realm of industrial maintenance, understanding the health of machinery is paramount. One of the most effective tools in this pursuit is Vibration Analysis technology. By examining the oscillations and vibrations of machinery, it’s possible to detect early signs of wear, misalignment, and other issues before they escalate into costly failures. In this article, we will delve into the different facets of Vibration Analysis technology and compare Handheld/Portable, Wireless, and Continuous Online Condition Monitoring solutions.

1. Handheld/Portable Vibration Analysis

Handheld/Portable Vibration Analyzers are compact devices designed for on-the-spot assessments of machinery. They are handy for routine checks (route-data collection), high-end troubleshooting with bump tests and coast-down applications, and corrective tasks such as balancing rotating machinery. These devices usually come equipped with accelerometers that measure vibrations in different axes, allowing technicians to collect data at specific points on a machine.

The Falcon is Acoem’s handheld vibration analyzer designed for beginners to experts alike.

Advantages

● Portability: Technicians/Engineers can carry these devices to various locations within a facility.

● Immediate Results: Data can be collected and analyzed in real-time, enabling quick decisions.

● Cost-Effectiveness: Initial investment costs are lower compared to more complex monitoring systems.

Limitations

● Limited Continuous Monitoring: Handheld analyzers provide snapshots in time. Continuous monitoring is not feasible without dedicated personnel.

● Dependency on Operator Skill: Interpretation of results may require a skilled operator, but modern tools have embedded AI diagnostic tools such as the Accurex™ Artificial Intelligence engine.

● Data Storage: Data needs to be manually recorded and stored for later analysis in a software platform such as the Acoem NESTi4.0.

2. Wireless Vibration Analysis

Wireless Vibration Analysis systems bridge the gap between portability and continuous monitoring. These systems typically consist of wireless sensors attached to machinery, which transmit data to a central server via a wireless network. This enables technicians to collect and access data remotely.

Acoem Sparrow Wireless Sensors w/ Gateway (Left) and Acoem Eagle Wireless Sensors w/ Gateway (Right)

Advantages

● Remote Monitoring: Technicians can access data from any location with internet connectivity.

● Timely Alerts: Anomalies can trigger automatic alerts, allowing for proactive maintenance.

● Historical Data Logging: Continuous monitoring provides a rich dataset for trend analysis and predictive maintenance.

Limitations

● Initial Investment: Setting up a wireless network and installing sensors may entail higher upfront costs.

● Network Dependence: Reliability is contingent on a stable network, which may not always be available in specific industrial settings.

● Battery Life: Wireless sensors require periodic recharging or battery replacement.

3. Continuous Online Condition Monitoring

Continuous Online Condition Monitoring represents the pinnacle of Vibration Analysis technology. It involves a network of sensors permanently attached to critical machinery, continuously transmitting data to a central monitoring system. This system employs advanced algorithms to detect deviations from regular operation and can monitor multiple varying operating states of rotating machinery.

An overhead view of Acoem’s MVX. Several inputs are available on a continuous system like this, to run multiple wired sensors to it at once.

Advantages

● Uninterrupted Monitoring: 24/7 surveillance of machinery health allows for early detection of anomalies.

● Predictive Analytics: Advanced algorithms can forecast potential issues, enabling proactive maintenance.

● Reduced Downtime: By addressing issues before they escalate, unplanned downtime is minimized.

Limitations

● High Initial Investment: Implementing a comprehensive online monitoring system can be a significant financial commitment.

● Complex Integration: Integrating existing control systems and databases may require expertise and time.

● Data Overload: Thanks to modern data reduction technology and cost-effective storage solutions, handling large volumes of data is now manageable, requiring robust analytical capabilities.

4. Vibration Protection Systems

A Vibration Protection System’s primary aim is to prevent damage by detecting excessive vibrations and shutting down the machine. It responds immediately when preset thresholds are surpassed, offering real-time, reactive protection. This system is well-suited for safeguarding specific, critical, and high-value machinery in environments where immediate shutdown protection is vital.

Advantages

● Improved Safety: Stabilizes machinery, reducing safety risks.

● Precision and Compliance: Maintains stable conditions for accuracy and ensures regulatory compliance.

Limitations

● Cost: Initial investment is usually very high.

● Installation Complexity: Requires expertise and may lead to more prolonged setup times.

● Maintenance Needs: Regular upkeep is essential for continued effectiveness.

● Frequency Limitations: May not address all vibration frequencies.

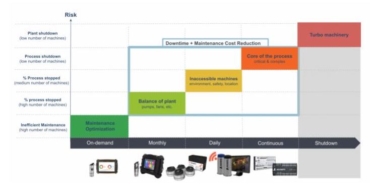

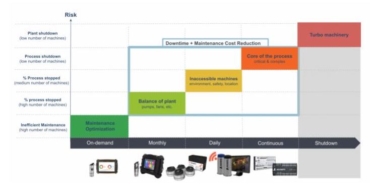

Strategy

The application of various data acquisition units can be effectively strategized using a straightforward approach illustrated in the chart below. This chart categorizes the data acquisition units based on two critical factors: the risk associated with the asset and the frequency of measurement. This method offers a clear framework for optimizing data collection efforts, ensuring that resources are allocated efficiently based on the importance of the asset and the need for frequent monitoring.

EcoSystem

Ideally, the goal is to seamlessly integrate the technologies above, operating within a unified ecosystem. This harmonious integration not only enhances efficiency but also facilitates seamless communication and synergy among various components. When different technologies work cohesively within a single ecosystem, they can unlock a higher level of performance and productivity, ultimately leading to a more streamlined and effective operational environment.

Conclusion

Vibration Analysis technology is an indispensable tool in modern industrial maintenance, offering insights into machinery health that can prevent catastrophic failures.

Choosing the right solution depends on the specific needs and resources of each facility. Handheld/Portable analyzers are suitable for route-data collection, troubleshooting, and balancing, while Wireless systems provide a balance between portability and continuous monitoring. For critical machinery, Continuous Online Condition Monitoring offers the most comprehensive and proactive approach to maintenance. A Protection System is essential for regulatory compliance and safeguarding machines of utmost importance, like turbines in nuclear facilities.

By investing in the right technology, industries can safeguard their assets and optimize operational efficiency. At Acoem, we offer a multitude of Condition Monitoring solutions that can help you improve the health of

your rotating machinery. If you and/or your organization are in the process of looking for the right Vibration Analysis solutions for your facility, Contact Us today and we would be glad to help!