Before scrolling past what may appear to be another boring article about fluting, VFD’s, grounding brushes and ceramic bearings, I urge you to read on and join in the discussion.

First let us quickly and briefly revisit the boring aspects of fluting. What is fluting, how can it be detected and how can it be prevented. Fluting is a form of bearing damage caused by AC or DC current discharging to ground through the bearing(s). Over the past 20+ years this issue has become increasingly significant. Both due to the amount of VFD’s being used and these VFD’s becoming increasingly powerful.

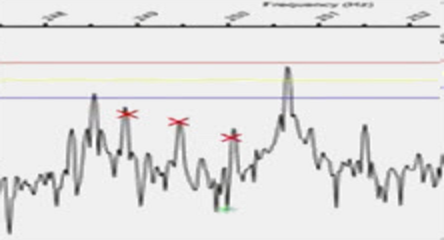

Fluting is a defect that can be easily identified through conventional vibration analysis methods, shaft voltage measurements or simply listening for that all to familiar growling being emitted from those rolling elements going over the signature fluted washboard bearing races.

Prevention has certainly evolved as well over the past 20+ years. When I first got my start in condition monitoring the remedy for fluting was to install a small carbon grounding brush on the motor shaft, that evolved to using a larger copper bristle brush, which evolved into full shaft grounding rings and then into ceramic bearings and ceramic sleeves in housings. All of which have failed to be the “be all end all” solution to electrical fluting on their own.

Now, on to the exciting stuff!

This may be a bold statement, but I’ve yet to see a fluted bearing fail due to the actual fluting of the raceways. In my experience, the sound emitted from a fluted bearing typically sounds much worse than the actual bearing condition and assets are therefore subsequently pulled from service earlier than needed. I do not believe there is a one size fits all standard for gauging severity of fluting. But that is a discussion for another time.

When electrical arcing occurs in the bearing, it chemically damages the grease over time. This damage decreases the grease’s lubricating properties, which causes excess heating and lubrication breakdown and leads to eventual catastrophic failure. Normally a cage failure, hence quick and catastrophic.

Which brings me to my main point. Why are all fluting articles the same? Why are they all focused on the motor? WHAT ABOUT THE DRIVEN COMPONENT??!!

Let us dive in.

In the world of plastic extrusion, fluting is a huge problem. Extrusion lines can have just one or multiple motor/gearboxes. Each one contributing to the lines layered film process. And of course, all on VFD’s and running at different speeds and loads. This makes for a fluting paradise.

During routine quarterly analysis of a single layer extruder, driven by a 500 HP DC motor, I had easily identified a fluting condition through simple use of an Acceleration reading. The motor had a big energy haystack out in 100K to 150K CPM range with spacings of BPFO and an overall amplitude of 6 g’s peak at 50% loading. The gearbox also shared the same results at lower amplitudes which I believed to be transferring from the motor.

I proceeded to put this asset on a “watch list” for almost 2 years with little escalation in severity, just extremely noisy (based on loading) from the fluting.

Eventually the motor was rebuilt (with fluting protection) and put back into service. Upon walking up to the freshly rebuilt motor, during my next quarterly analysis, I heard that all too familiar fluting growl. Analysis once again detected fluting present. It was much lower at the motor but still present. Further analysis, to my surprise, detected the fluting signature to now be dominant at the gearbox. How could this be?! Was it possible these currents not only discharged through the motor bearings but also jumped the grid style coupling to ground out through the gearbox bearings??!! Everything I have ever read and been taught was that fluting was a form of damage done to electric MOTOR bearings as current from a VFD passes through them to ground.

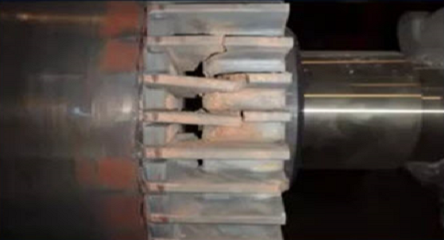

At this point I requested that the unit be shut down at the customers convenience and that I perform a good old visual inspection. To my amazement every bearing inside this triple reduction, single screw gearbox had fluting on both the inner and outer race.

So, the question is what happens to fluted bearings that operate in oil? Well, here is the crazy part, this gearbox is going on 10 years of running with fluted bearings with absolutely zero issues. I have also since identified this phenomenon in other driven components throughout industry.

Answer…. Let’s discuss via the comment section!

When it comes to fluting remember to think beyond the motor.

Very Interesting!

Hello good morning.

It is observed that in our case, the gear box input shaft drive end bearing (double row, spherical roller bearing) drive side race fluting on inner and outer races. Motor is 700kw VFD drive.

I’m curious about grounding, whichever pathway provides a lower resistance path to the earth ground is where the stray rotor currents will travel to.

Hi sir

Can we detect fluting defect at the initial stage by using air born ultrasound ?