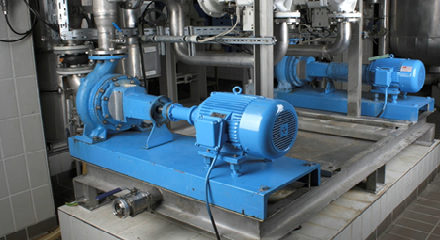

A worn-out bearing may have many causes. But, in most cases, the source of the problem is misalignment.

High resilience from the shaft may result in bearing damage that affects your machines and leads to production inefficiencies.

PRUFTECHNIK, Inc., the maker of ROTALIGN and OPTALIGN alignment solutions, has been setting new standards in machine and shaft alignment for than 35 years.

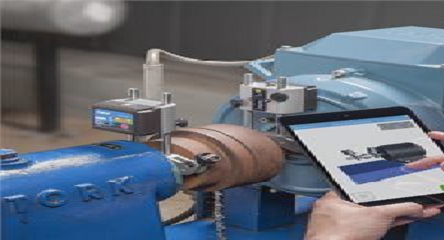

Now, this unit of Fluke Reliability and the Fluke Corporation has unveiled its cutting-edge sensALIGN family — the laser/sensor measurement technology that makes the difference in shaft alignment.

PRUFTECHNIK’s sensALIGN measurement technology for precision shaft alignment is unique in today’s market.

Some still trust antiquated practices

Let’s see how alignment conditions were measured in the past. Measuring by straightedge and dial gauge were the standard. Even today, some specialists still trust in this ancient technology.

It is not bad to use straightedge and dial gauge, but it is time-consuming and requires meticulous and skillful personnel when it comes to getting accurate measuring results.

To accurately measure the angularity of a misaligned machine, it takes at least two measurements on a dial gauge. It is extremely important to put distance between the first measuring point and the second one. The further the distance, the more accurate and precise the measurement.

To measure offset, you repeat the measurement in another clock position different from your first two measurement points. As you can see, this job is time-consuming, and for specialists only.

PRUFTECHNIK has made all this redundant with its sensALIGN laser/sensor technology.

Combining two measurements into one

As we just noted, measuring angularity and offset always takes at least two measurements. The sensALIGN technology does it all with one single measurement.

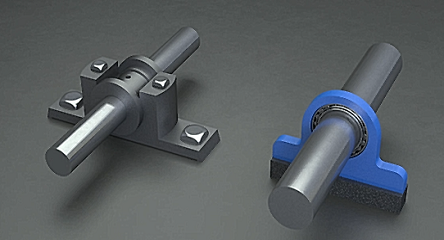

The single laser beam is shot into the sensor center, where it is focused and minimized by an optical lens. A semipermeable mirror splits the laser beam into two, deflecting one beam onto the front detector and the second onto the rear detector.

This distinctive global technology guarantees that the distance between the first and the second measurement point will always be the same, exact distance. The front detector equals the first dial gauge measurement point, while the rear detector equals the second dial gauge measurement point.

Based on this, the distance between the laser and sensor can be either set down to zero millimeters or even up to 10 meters.

This high-performance technology guarantees precision and repeatability.

Now, let’s see and understand how precise PRUFTECHNIK’s sensALIGN detectors are. The resolution of each detector is at 0.001 millimeter; that means 1 micrometer.

And since the detector areas are given in x- and y-axis, PRUFTECHIK’s SENSALIGN technology can measure shaft angularity and offset in one single shaft rotation.

Live Move and Live Trend features

Additionally, the Live Move feature, which enables aligning the shaft with the laser/sensor heads mounted to directly control the alignment process, can be started and terminated in any position.

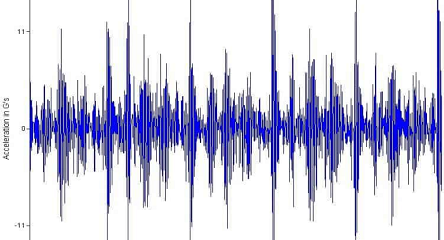

Another special feature that only PRUFTECHNIK provides is Live Trend, based on the x- and y- split detection areas. The sensALIGN laser/sensor technology can record the thermal growth of the machine while it is running.

The sensALIGN measurement technology is available with ROTALIGN touch and OPTALIGN touch.

ROTALIGN touch is featuring the high-performance sensALIGN 7 laser/sensor heads, including all PRUFTECHNIK intelligent shaft-alignment features such as the advanced multi-coupling measurement and Live Move of up to 6 shaft couplings at a time.

OPTALIGN touch is equipped with the powerful sensALIGN 5 laser/sensor technology. This alignment device is the latest standard in every maintenance workshop.

It can be easily upgraded with a sensALIGN 7 laser/sensor unit for full access to PRUFTECHNIK intelligent alignment features, including alignment of vertical machines and extended cardan shaft features.

For visuals on how sensALIGN works, watch this PRUFTECHNIK video.