Increased Revenue Results from Expanded Testing Capabilities

Every successful business works to increase revenue so that the company can grow and continue to provide better products or services to their customers. Growing companies typically make investments in state-of-the-art tools and equipment so that they may expand their capability to serve their customers. One such company, Koontz-Wagner Services, has been able to capitalize upon several opportunities since acquiring new energized and de-energized motor testing equipment last year.

Koontz-Wagner Services is a leading Midwest provider of motor repair and maintenance services for rotating equipment, electric motors, generators and mechanical power transmission components along with electrical contracting services which range from short order services to design and complex large project services.

Leading the effort to obtain sophisticated motor testing equipment was Kenneth L. Patterson, Koontz-Wagner’s highly skilled and extremely proactive predictive maintenance manager. After conducting extensive research on different types of motor testing equipment that was available on the market, Patterson decided to purchase ALL-TEST Pro motor testing products through Sun Infrared Technologies in January 2015.

Patterson chose two hand-held, de-energized motor testers: the ALL-TEST PRO 5™ and ALL-TEST PRO 31™, in addition to an energized motor tester: the ALL-TEST PRO On-Line II™. Patterson’s 12-person predictive maintenance team participated in a standard post-sale training session conducted by ALL-TEST Pro. The PdM team was thoroughly educated on how to perform advanced non-destructive motor testing and analysis for both de-energized motor circuit analysis and energized electrical signature and power analysis.

Putting the Motor Testing Products to Work

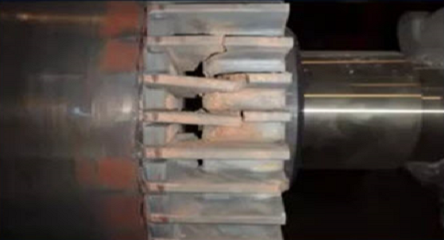

As a full-service company, Koontz-Wagner has a motor repair division, a predictive maintenance division, and a construction division. Koontz-Wagner’s motor repair division made immediate use of the de-energized motor testing equipment by streamlining their inspection processes. “Using the AT5™ and the AT31™ has helped us reduce the time it takes to understand the general condition of a motor,” explains Patterson. “The AT5™ motor circuit analyzer shows us if there are bad connections, ground faults, it checks the winding, and lets us know if there are air gaps, contamination, or broken bars – it gives us a pretty good picture of the motor’s health within just a few minutes, which is important because reducing the time it took us to inspect a motor has enabled us to lower the cost of that initial inspection,” continues Patterson. “The incoming inspection fees we had been charging customers was a little high compared to our competitors, so changing our inspection process has allowed us to lower those initial inspection fees and become more competitive.”

Koontz-Wagner service technician, Erik Lehman, utilizes the ALL-TEST PRO 5™ to perform initial inspection of a 50 HP motor in the repair shop.

Increasing Business Opportunities

In September of 2015, Koontz-Wagner Maintenance Services began using their portable de-energized motor testing equipment outside the repair shop. Having a long-time relationship with a large automotive supply company, Koontz-Wagner saw an opportunity to provide additional value-added support to their customer. This automotive supplier maintained an inventory of approximately 700 spare motors. Over the course of three months, Koontz-Wagner’s predictive maintenance technicians went through this inventory to check the health and condition of all the spare motors. “Out of that inventory of about 700 motors, we found that about 100 of these motors required maintenance,” explains Patterson. “We used the AT5™ on-site, which was great because it generates reports quickly, so it was ideal for that particular project. And now we are scheduling these motors to come into our motor repair division for service.”

“Using the AT5™ and the AT31™ has helped us reduce the time it takes to understand the general condition of a motor,” explains Patterson.

Ken Patterson, head of the predictive maintenance division at Koontz-Wagner, tests a 9000 HP motor.

Generating Revenue with Energized Testing

Energized testing has become another area of sales growth for Koontz-Wagner. “I have generated quite a bit of income using the ALL-SAFE PRO®,” declares Patterson. The ALL-SAFE PRO® is the adapter installed inside the electrical cabinet which works with the ATPOL II™ energized testing instrument.

This adapter provides the necessary signals to help preventive maintenance professionals understand the condition of operating motors with minimal risk, eliminating the need for bulky, protective gear.

Koontz-Wagner’s team of electricians, employed by their construction division, has installed 15 ALL-SAFE PRO® adapters inside different customers’ electrical cabinets. Then the Koontz-Wagner predictive maintenance team uses the ALL-TEST PRO On- Line II™ energized tester to obtain data on operating motors and further support their customers’ condition-based monitoring and predictive maintenance programs.

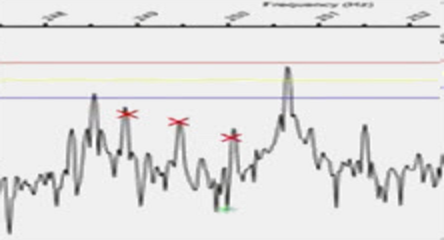

“I have performed vibration testing for one of our automotive customers, and the ATPOL II™ has confirmed the results of those vibration tests,” shares Patterson. “Maintaining the health of this 200vHP compressor motor is critical because it operates to provide air to the automotive supplier’s facility.”

Patterson prepares to install an ALL-SAFE PRO® so he can use an ATPOL II™ to perform energized motor testing.

Conclusion

“This testing equipment is helping our company in many ways, and I’m hoping to expand our capabilities in 2016 using these instruments,” states Patterson. Koontz-Wagner has seen their profits increase by 10% as a result of employing ALL-TEST Pro motor testing equipment, proving there are real benefits to investing in modern tools and technology.