The Company

During the demonstration of an ALL-TEST PRO 5TM Motor Circuit Analysis instrument (de-energized motor tester) a member of ALL-TEST Pro Technical Support Team tested a 10HP, 4-pole, T-frame motor that had been removed from a large corn wet milling facility.

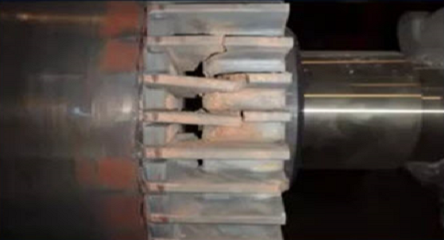

This corn wet milling facility, which processes about 14,000 bushels of corn each day, pulled this 10HP motor from one of their conveyor belts. The motor had exhibited a “phase fault” on the variable frequency drive (VFD) that controlled it. The maintenance staff at the corn wet milling facility had determined the motor was “bad” through a process of elimination that involved a series of part replacements that were unsuccessful in restarting the motor. The motor was then sent to the motor distributor’s repair facility where it was tested using two ‘traditional’ motor testing technologies – a surge test and an inductance-based test – both of which provided no definitive results.

Condition of Motor Revealed by AT5™ De-energized Testing Instrument

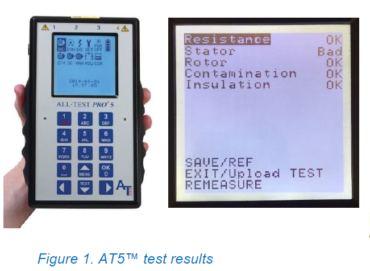

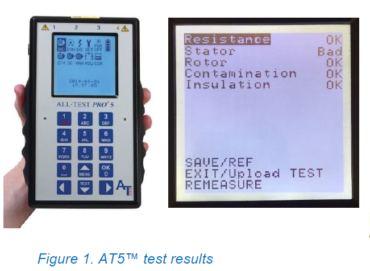

The AT5™ motor circuit analyzer is battery-powered, hand-held, and weighs less than 2 lbs. After connections were made to the three phases of the motor, a static test was performed. Next, the motor shaft was manually moved during the dynamic portion of the 3-phase test, and at the end of the test, the instrument showed the results (the entire test takes about 2 minutes).

Unlike the unsuccessful surge test (which applies high voltage to the motor coils) and the inconclusive inductance-based test, the AT5™ immediately detected a stator winding fault (see Figure 1).

While the IND test using the DYNamic option indicated there was a fault in the stator winding, it’s important to point out that it is often impossible or impractical to perform a “Dynamic” test (which requires the slow and smooth rotation of the motor shaft) in the field due to motors being physically coupled to the process or being located in an inaccessible spot. If it is not possible to perform a Dynamic test, it is still possible to use the AT5™ de-energized motor testing instrument for comparative analysis.

Performing Comparative Analysis using a Reference Test Value Static (TVSTM)

AT5™ patented and patent-pending methods include obtaining a Reference Test Value Static (TVS™), where an initial static test is performed and a Reference TVS™ value is established. Reference TVS™ are stored in the instrument’s internal memory, or can be transferred to computer software, and subsequent test results can be immediately compared to the Reference TVS™ to instantly show developing problems or changes with the stator or squirrel-cage rotor (the comparison can be viewed directly on the AT5™ instrument’s large, easy-to-view display). TVS™ can be used as a Reference value for that specific motor or other motors of the exact same manufacturer/type.

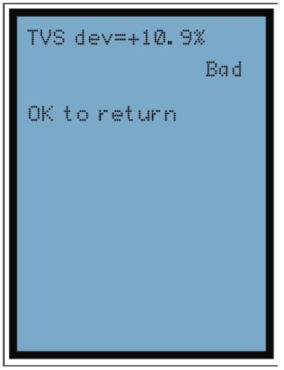

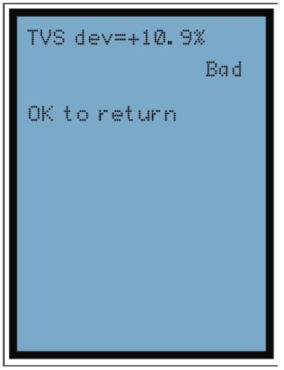

This particular case presented the opportunity to demonstrate comparative analysis using TVS™. An identical motor was retrieved from the distributor’s stock and a Static test was performed with the AT5™. It was immediately noticed that there was a 10.9% difference between the TVS™ value of the new motor and that of the known “bad” motor. This is clearly outside the 3% alarm and very plainly indicates that the known bad motor is in a different condition from its identical twin.

Lessons Learned

In a troubleshooting situation, comparing TVS™ can be accomplished by testing from the output of the VFD without removing the motor or disconnecting the load. This comparison test would have allowed the mill’s maintenance technicians to immediately confirm that the condition of the motor had changed from its original installed condition. This test, along with the fault indication on the Variable Frequency Drive, would have correctly identified the reason for the motor shut down, and time and money would not have been wasted by just replacing parts.